- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Batch Determination of components in the Productio...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

07-23-2018

1:37 PM

Hi All,

Table of Contents

What is mean by Batch Determination in the Production Orders?

Business scenario

Configuration data to be maintained for Batch Determination

Define the Condition Table

Define Access Sequence

Create the Search Strategy

Create the Search Procedure T Code: OPLG

Assign Search Procedure in Order Type Dependent parameters (OPL8

Create PP Master Data

Create Batch Determination Master Data

Create the Batch Search Strategy using the T Code: COB1

Selection Class can be created using the T Code: BMC1/CL02

Sort Rule can be created using the T Code: CU70

Transaction data

Create the Production Order using the T Code: CO01

Release the Production Order using the T Code: CO02

Perform Batch Determination of the Components using T Code: CO02

Goods Issue to the Production Order using T Code: MIGO

Confirmation of the Production Order using the T Code: CO15/CO11N

Goods Receipt of the Production Order using the T Code: MIGO

Automatic Batch Determination in the Production Order

Batch Determination is the Process, by which system is able to assign/propose the suitable Batches for the Batch managed components in the Production Order, which meets desired Selection Criteria/business requirement

In the Production of the Finished Material (Ex: FG-BATCH), using one of the Batch managed component (Ex: RM2-BTACH), System should pick up only those Batches, for which Country of Origin is maintained as US (USA), & also if there are more than one Batch, those selected Batches should be sorted by the Ascending Order of their Self Life Expiration Date, during the Batch Determination Process manually.

SPRO>> Logistic General >> Batch Management >> Batch Determination & Check>>Condition tables>> Define Production Order Condition Tables

Create the Search Strategy

Create the Search Procedure (T Code: OPLG)

**** **** *****

Create all the necessary PP Master Data. Ref. the below Master data used in this scenario

Finished Material: FG2-BATCH

Component Material: RM2-BATCH

BOM: 00000287

Work Center: MACHINE1

Routing: 50000055

Production Version: V001

With the Organizational Data >>> Plant: 1010 & Storage Locations: 101A & 101B

Create the material Master for the Header Material as well as for all the components required to produce the Header Material using the Transaction Code: MM01

Note: For all the Batch managed component Materials, you need to make sure

Material Master of the Header Material # FG2-BATCH

Material Master of the Component Material # RM2-BATCH

Material Master of the Component Material # RM2-BATCH

Create the BOM, for the Header Material # FG2-BATCH, using the T Code: CS01.

Create the BOM, for the Header Material # FG2-BATCH, using the T Code: CS01.

With one Component # RM2-BATCH, which is Batch managed material (As Example)

Create the Work Center using the T Code: CR01

Create the Work Center using the T Code: CR01

Create the Routing for the Header Material using the T Code: CA01

Create the Production Version for the Header Material(Ex: FG2-BATCH) T Code: MM02/C223

Search Strategy contains the Selection Criteria & Sort Rule to be followed

Please keep it in mind, at least one of the Characteristics of this Selection Class should be the same with the Classification of Characteristics in the Material Master & also maintain the Value for at least one or more characteristics in the Selection Class (As shown below)

Production Order: 1003102, Created >>> As of now, no batch number is assigned for the Header Material & also for the component

Once, the Order is Release, System will assign the Batch Number for the Header Material (As per Production Order Scheduling Profile settings maintained)

Select the Line Item, for which Batch Determination to be done & & Click on Batch Determination Icon

Then in the Next Screen, System will pull up all the Batches which meets the Selection Criteria.

Also, selected batches are sorted as per the Sort Rule maintained

Stock updated in the respective Storage location

For this functionality of automatic Batch Determination of the Component Materials in the Production Order, need to maintain for the Batch Managed Component(s), in the Material Master, in MRP 2 View, with the Batch Entry Option =3. Rest of the above settings remains the same.

With this setting, System assigns the Batch Number automatically, for the Component Material, during the Release of the Production Order

***** ***** ***** ***** ***** **

Kindly advice for any further improvements/changes, which makes it, as the most useful document

Many Thanks & Regards: Raja Sekhara Reddy Bannuru.

Steps for the Batch Determination in the Production Order in S/4 HANA 1709

Table of Contents

What is mean by Batch Determination in the Production Orders?

Business scenario

Configuration data to be maintained for Batch Determination

Define the Condition Table

Define Access Sequence

Create the Search Strategy

Create the Search Procedure T Code: OPLG

Assign Search Procedure in Order Type Dependent parameters (OPL8

Create PP Master Data

Create Batch Determination Master Data

Create the Batch Search Strategy using the T Code: COB1

Selection Class can be created using the T Code: BMC1/CL02

Sort Rule can be created using the T Code: CU70

Transaction data

Create the Production Order using the T Code: CO01

Release the Production Order using the T Code: CO02

Perform Batch Determination of the Components using T Code: CO02

Goods Issue to the Production Order using T Code: MIGO

Confirmation of the Production Order using the T Code: CO15/CO11N

Goods Receipt of the Production Order using the T Code: MIGO

Automatic Batch Determination in the Production Order

What is mean by Batch Determination in the Production Orders?

Batch Determination is the Process, by which system is able to assign/propose the suitable Batches for the Batch managed components in the Production Order, which meets desired Selection Criteria/business requirement

Business scenario

In the Production of the Finished Material (Ex: FG-BATCH), using one of the Batch managed component (Ex: RM2-BTACH), System should pick up only those Batches, for which Country of Origin is maintained as US (USA), & also if there are more than one Batch, those selected Batches should be sorted by the Ascending Order of their Self Life Expiration Date, during the Batch Determination Process manually.

Configuration data for Batch Determination

Create the Condition Table(T Code : OPLD)

SPRO>> Logistic General >> Batch Management >> Batch Determination & Check>>Condition tables>> Define Production Order Condition Tables

Define Access Sequence

Create the Search Strategy

In the Search Strategy, assign the Access Sequence defined above & if required, the Selection Class & Sort sequence

Create the Search Procedure (T Code: OPLG)

Search Procedure in linked with the Strategy Type(s), defined in the above step

Assign Search Procedure in Order Type Dependent parameters ( T Code: OPL8)

**** **** *****

Create PP Master Data

Create all the necessary PP Master Data. Ref. the below Master data used in this scenario

Finished Material: FG2-BATCH

Component Material: RM2-BATCH

BOM: 00000287

Work Center: MACHINE1

Routing: 50000055

Production Version: V001

With the Organizational Data >>> Plant: 1010 & Storage Locations: 101A & 101B

Create the material Master for the Header Material as well as for all the components required to produce the Header Material using the Transaction Code: MM01

Note: For all the Batch managed component Materials, you need to make sure

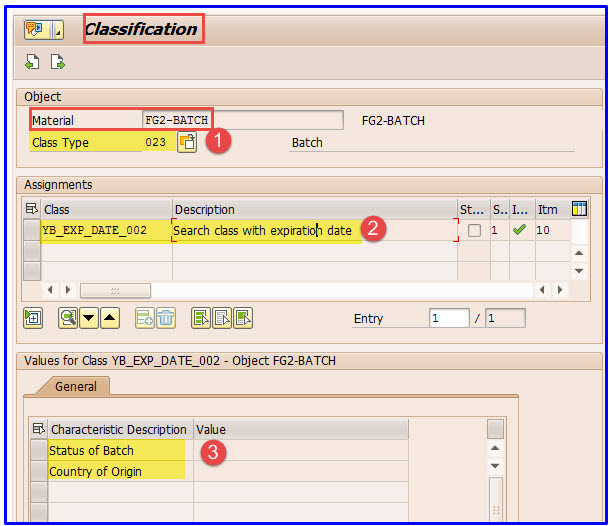

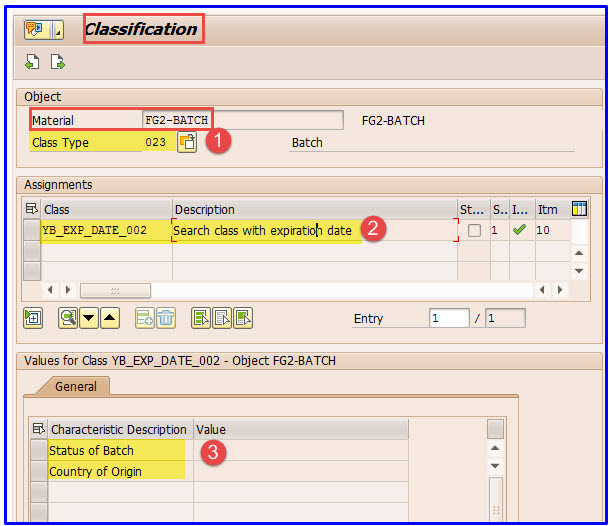

- Classification view is maintained with the Class Type: 023

- Class is assigned

- Characteristics are maintained &

- Batch Management is activated (For Header Material, its Optional)

Material Master of the Header Material # FG2-BATCH

Material Master of the Component Material # RM2-BATCH

Material Master of the Component Material # RM2-BATCH

Create the BOM, for the Header Material # FG2-BATCH, using the T Code: CS01.

Create the BOM, for the Header Material # FG2-BATCH, using the T Code: CS01.With one Component # RM2-BATCH, which is Batch managed material (As Example)

Create the Work Center using the T Code: CR01

Create the Work Center using the T Code: CR01

Create the Routing for the Header Material using the T Code: CA01

Create the Production Version for the Header Material(Ex: FG2-BATCH) T Code: MM02/C223

Create Batch Determination Master Data

Create the Batch Search Strategy using the T Code: COB1

Search Strategy contains the Selection Criteria & Sort Rule to be followed

Selection Class can be created using the T Code: BMC1/CL02

Please keep it in mind, at least one of the Characteristics of this Selection Class should be the same with the Classification of Characteristics in the Material Master & also maintain the Value for at least one or more characteristics in the Selection Class (As shown below)

Sort Rule can be created using the T Code: CU70

Transaction data

Create the Production Order using the T Code: CO01

Production Order: 1003102, Created >>> As of now, no batch number is assigned for the Header Material & also for the component

Once, the Order is Release, System will assign the Batch Number for the Header Material (As per Production Order Scheduling Profile settings maintained)

Release the Production Order using the T Code: CO02

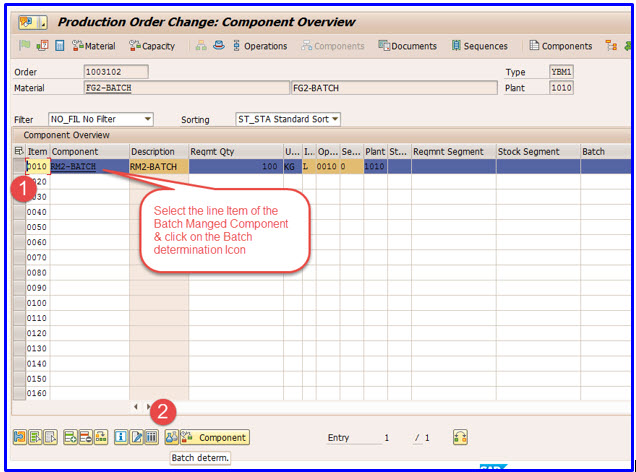

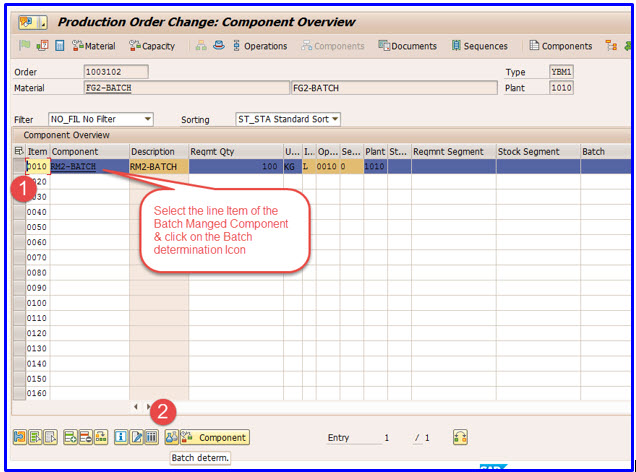

Batch Determination of the Components using T Code: CO02

Select the Line Item, for which Batch Determination to be done & & Click on Batch Determination Icon

Then in the Next Screen, System will pull up all the Batches which meets the Selection Criteria.

Also, selected batches are sorted as per the Sort Rule maintained

Confirmation of Prod. Order using the T Code: CO15/CO11N

Goods Receipt of Production Order using the T Code: MIGO

Stock updated in the respective Storage location

Automatics Batch Determination

For this functionality of automatic Batch Determination of the Component Materials in the Production Order, need to maintain for the Batch Managed Component(s), in the Material Master, in MRP 2 View, with the Batch Entry Option =3. Rest of the above settings remains the same.

With this setting, System assigns the Batch Number automatically, for the Component Material, during the Release of the Production Order

***** ***** ***** ***** ***** **

Kindly advice for any further improvements/changes, which makes it, as the most useful document

Many Thanks & Regards: Raja Sekhara Reddy Bannuru.

- SAP Managed Tags:

- MAN (Manufacturing),

- MAN Batch Management,

- MAN Production Planning (PP)

18 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Customizing

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

Ledger Combinations in SAP

1 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

POSTMAN

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

S4HANACloud audit

1 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP CI

1 -

SAP Cloud ALM

1 -

SAP CPI

1 -

SAP Data Quality Management

1 -

SAP ERP

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

Time Management

1 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Quantity Distribution in Enterprise Resource Planning Blogs by SAP

- Goods movement of errors because of account assignments in Enterprise Resource Planning Q&A

- Avail check showing 12/31/9999 for E/52 materials in Enterprise Resource Planning Q&A

- After production order release Batch not creating for component screen materials in Enterprise Resource Planning Q&A

- Recap of SAP S/4HANA 2023 Highlights Webinar: Manufacturing in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 |