- SAP Community

- Groups

- Interest Groups

- Enterprise Architecture

- Knowledge Base

- Application Choices and Decisions for The Inbound ...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

on 03-25-2024 8:00 AM

Summary

This article seeks to provide guidance on deciding the most suitable target application architecture to support Inbound Supply Planning needs of an organization, in the context of Source to Pay end to end cycle.

With SAP IBP and S/4HANA both delivering solution capabilities around Inbound Supply Planning, enterprises now have multiple options to choose from and need to make their selection by comparing their organization’s business capability requirements to the solution capabilities the different applications offer.

The licensing aspects of the components discussed should be considered during target architecture design and is beyond the scope of this evaluation.

Business Requirements

Purpose

Inbound Supply Planning is the process of deriving the procurement requirements for direct physical items like raw materials, spare parts, components, sub-assemblies etc. by linking them to the actual or forecasted demand of the finished product.

Basic Process

Input

- Firm and Forecasted Demand for Finished Goods

- Bill of Material for Finished Goods

- Available Stocks of Raw Materials, Spares etc.

- Business Roles : Material Planner, Maintenance Planner, Production Planner, Sales Planner

Process Flow

- Based on firm and forecasted finished product demand, dependent requirement of raw materials are formulated

- These dependent requirements are then compared against current stocks, taking into account, buffer and safety stocks

- The delta between existing and required quantity net buffer and safety stock reflects the new procurement requirement, which is thereafter either routed for production or purchase

Business Roles : Material Planner, Maintenance Planner, Production Planner, Sales Planner

Output

- Inbound Supply Planning creates a set of planned/ production orders or purchase requisitions, depending on whether the required raw material or spares are produced internally or purchased from an external supplier

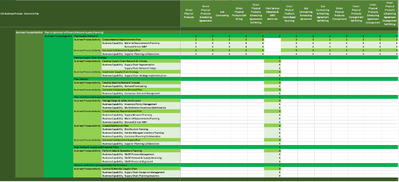

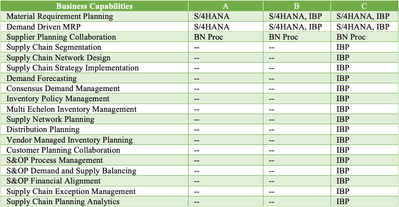

Business Capabilities

Supply Chain Segmentation

- Ability to define subnetworks and apply supply chain policies

Supply Chain Strategy Implementation

- Ability to translate overall supply chain strategy into tactical and operational controls

Supply Chain Network Design

- Ability to define nodes in a supply chain network of an organization and how they interconnect

S&OP Process Management

- Ability to define cyclical planning processes, assign individual or group tasks and monitor through completion

S&OP Demand and Supply Balancing

- Ability to aggregate demand signals and arrive at consensus demand

- Ability to generate a balanced rough-cut capacity plan

S&OP Financial Alignment

- Ability to align operational plans with financial goals and objectives

- Explore alternative plans that drive operational activities toward achieving strategic goals

Demand Forecasting

- Ability to generate a mathematical projection of demand using statistical and machine learning techniques, including analysis and preparation of data as well as automation of this process

- Includes forecast for products that are new to the business

Consensus Demand Management

- Ability to measure, analyze, adjust, and collaborate around a forecast, including driver analysis, error analysis and bias calculations

Inventory Policy Management

- Ability to set the parameters and controls that dictate how inventory is to be managed from a planning perspective

Multi-Echelon Inventory Optimization

- Ability to generate stock targets plans (e.g. define reorder points and safety stock) for a multi-echelon (network and BOM) environment, while taking into consideration demand / supply / production variability and service level %, to optimize inventory levels maximizing the performance-cost ratio

Supply Network Planning

- Ability to model and plan the entire network while netting demand requirements back to the plants

Demand Driven MRP

- Ability to consider only true demand

- It enables immediate creation of individualized products at the highest service levels with the lowest possible inventory along all bill of materials levels

Distribution Planning

- Ability to plan location transfers on a short-term horizon while taking into account demands and inventory targets

Vendor Managed Inventory Planning

- Ability to perform the full process of collaboration and managing your customer's demands, inventory, and replenishments with sales order creation as output of planning which is sent to ERP

Material Requirement Planning

- Ability to plan material requirements

- This typically includes planning (exploding) the bill of materials (BOM), creating purchasing recommendations, and providing operational plan proposals by taking lead times or routing information into account for requirement date calculation

Customer Planning Collaboration

- Ability to collaborate on forecast data downstream with trading partners such as customers, wholesale sites, and distributors

Supplier Planning Collaboration

- Ability to collaborate on forecast and inventory status upstream with suppliers and subcontractors

Supply Chain Exception Management

- Ability to quickly detect disruptions to the supply chain and effectively manage alerts

Supply Chain Planning Analytics

- Ability to leverage best-in-class analysis and visualization capabilities to support reporting directly within the business applications

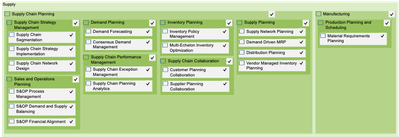

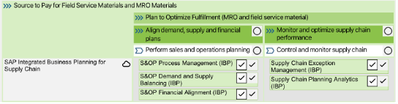

Distribution of Business Capabilities in the Inbound Supply Planning Process

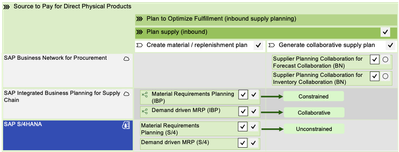

Solution Options

- SAP S/4HANA (private and public cloud)

- SAP Integrated Business Planning for Supply Chain (IBP)

- SAP Business Network for Procurement (BN Proc)

Characterization of the Solution Options

Common Process Variants

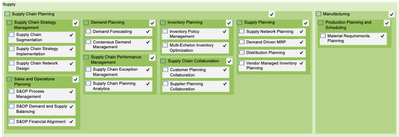

Material Requirements Planning – Unconstrainted

For more information, please refer to the best practice Material Requirement Planning (J44) and Procurement of Direct Material (J45).

Material Requirements Planning – Constrained

For more information, please refer to the best practice IBP for Sales & Operations – Demand Review (2BQ), IBP for Demand Planning (11V) and IBP Integration of Planned Independent Requirements to SAP S/4HANA (4NO).

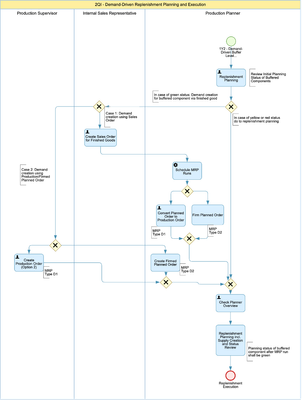

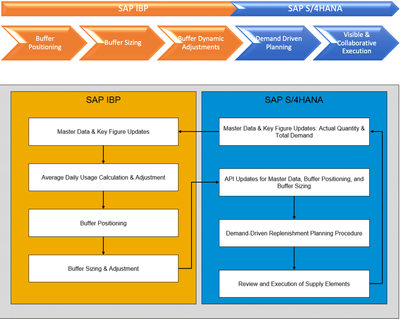

Demand Driven Replenishment (Pull Strategy)

For more information, please refer to the best practice Demand Driven Replenishment Planning and Execution (2QI) and Demand Driven Buffer Level Management (1Y2). For an understanding of how the end to end Demand Driven Replenishment process can run exclusively in S/4HANA, please refer to this SAP HELP documentation.

Demand Driven Replenishment (Pull Strategy) – Collaborative

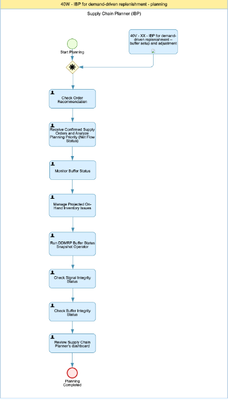

For more information, please refer to the best practice Demand Driven Replenishment – Strategic Buffer Positioning (40U), Demand Driven Replenishment – Buffer Set Up & Adjustment (40V) and Demand Driven Replenishment – Planning (40W). For an understanding of how the end to end Demand Driven Replenishment process can run collaboratively between IBP and S/4HANA, please refer to this SAP HELP documentation.

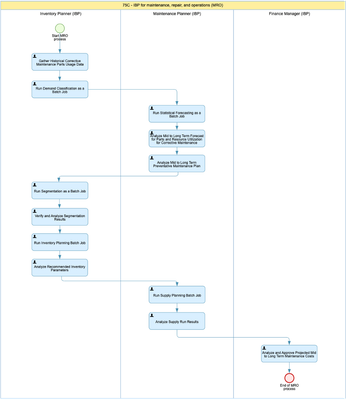

Maintenance, Repair and Operations (MRO)

For more information, please refer to the best practice IBP for Maintenance, Repair and Operations (75C).

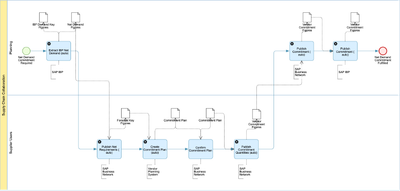

Collaborative Supply Planning

For more information, please refer to the best practice 1.2.12 Forecast Collaboration IBP – Integrated (SP-2767) and 1.2.12 Forecast Collaboration ERP – Integrated (SP-2766).

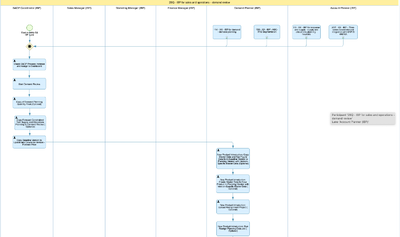

Capability Distribution Across E2E Process Variants

Criteria to determine the most suitable target solution

Solution Capability Based

Inbound Supply Planning – Direct Physical Products

Inbound Supply Planning – MRO Materials

Business Process/ IT Parameter Based

Additionally, the following business and IT considerations may also be applied in certain cases, to arrive at the most appropriate solution :

- Does the organization wish to drive their material requirement planning with heuristics and optimizer algorithms?

- Does the organization deal with large quantities of high/ moderate value spares?

- Are there frequent occasions where the suppliers upload their commitment quantities directly into the organization’s system?

Decision Tree

The architectural decision with the listed solution(s) are complementary and not mutually exclusive. Since the same set of business capabilities are sometimes enabled by multiple solution capabilities, the choice of application is tied more to the addressable business process variants than differential capabilities of the products.

Accordingly, the following 3 major E2E process variants (A – C) discussed in the previous two sections may be used to arrive at application decisions :

- Inbound Supply Planning of Direct Materials – Unconstrained

- Inbound Supply Planning of Direct Materials – Constrained

- Inbound Supply Planning of MRO Materials

Conclusion

- Both S/4HANA and IBP has Material Requirement Planning capabilities – with S/4HANA, planning is done without constraints, while with IBP, heuristics and optimization algorithms can be used to build in real life limitations for a more realistic, constrained, inbound supply planning for direct materials

- While it is absolutely possible to run inbound supply planning exclusively with S/4HANA, typically, complex, geographically spread out organizations with multiple manufacturing facilities and distribution centres tend to need optimized planning eventually and should go for IBP on top of S/4HANA

- Organizations with extensive spares volume of substantial value, also need to go for both S/4HANA and IBP

- For collaborative planning with suppliers, additionally, Business Network for Procurement will be required