- SAP Community

- Groups

- Interest Groups

- Enterprise Architecture

- Knowledge Base

- Solution Options for Manufacturing Operations Mana...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

on 02-12-2024 8:00 AM

Summary

In this article we describe alternative options of an SAP application landscape that can provide Manufacturing Operations Management (MOM) capabilities. A list of criteria is intended to help evaluating the options and to make the right choice for a customer, taking their situation and preferences into account.

Business Requirements

The business requires the ability to manage all operations during manufacturing, including scheduling, sequencing, and dispatching of operations, activities, resources, equipment, and material, as well as capturing relevant data.

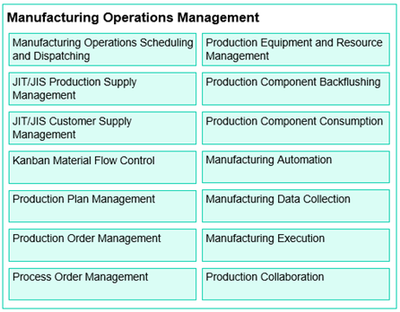

According to SAP Reference Business Architecture the Manufacturing Operations Management (MOM) business area comprises the following capabilities (available to view in SAP Signavio Process Explorer

Solution Options

SAP’s product portfolio offers the following manufacturing solutions which provide Manufacturing Operations Management (MOM) capabilities:

- SAP S/4HANA

- Manufacturing core

- Manufacturing for production engineering and operations - SAP Digital Manufacturing

SAP Manufacturing Execution (ME) and SAP Manufacturing Integration and Intelligence (MII) are still available; however, the maintenance of the latest release (SAP ME 15.5, SAP MII 15.5) will expire by end of 2030 (SAP Maintenance Strategy: Maintenance 2040), and there are no plans for further releases of SAP. Therefore, SAP ME+MII are not considered as potential solutions in this article.

Moving forward, the platform of innovation is SAP Digital Manufacturing as a key component of SAP’s strategic manufacturing solution portfolio.

In the context of MOM capabilities, SAP S/4HANA provides core manufacturing execution and analytics functionality. SAP Digital Manufacturing solution is a cloud-based manufacturing execution system (MES).

In a typical manufacturing environment, the core ERP solution is complemented and integrated with an MES/MOM system. In the overall application architecture SAP Digital Manufacturing is not an alternative to S/4HANA, but the MES required to enhance and complement the core ERP manufacturing capabilities.

Characterization of the Solution Options

The brief description below focuses on the MOM context only and is not intended to provide the full scope of the capabilities of the products. For additional details please visit Manufacturing Software | MES & IIoT Solutions | SAP

SAP S/4HANA

SAP S/4HANA has all the standard core capabilities to support basic production operations. Production Operations (Execution and Control) enables you to make the necessary preparations required for production, to coordinate the exchange of data relevant to production, and to document the production progress:

- Production Control

Control full shop floor production for handling materials, BoMs, recipes, routings, batches, parts, components, work centers, and resources, all the way up to the finished products using central cockpits to minimize bottlenecks and mitigate risk.

- Production Execution

Execute, control, monitor, and confirm manufacturing with real-time data from shop floor, contract manufacturers and suppliers. Transfer planned orders, release production orders, confirm operations, and track work in progress.

Production Operations supports various manufacturing environments:

- Discrete Manufacturing

- Project Manufacturing Management and Optimization (PMMO)

- Process Manufacturing

- Kanban (PP-KAB)

- Repetitive Manufacturing (PP-REM)

- Just-in-Time Processing

Production Engineering and Operations

SAP S/4HANA Manufacturing for production engineering and operations (PEO) is an SAP S/4HANA product extension expanding S/4 Enterprise Management core discrete manufacturing capabilities with enhanced 3D visualization, production process planning, manufacturing change management, shop floor production order and operations management supporting complex manufacturing scenarios.

SAP PEO is suitable solution for Discrete Manufacturers for complex ETO and CTO+, CTO assembly processes, especially those making highly engineered products in low volume, large items. Long lead times, ongoing and high frequency of engineering changes to be incorporated during production. Relevant industries include IM&C and A&D whereby final assembly of a large final product is comprised of many complex subassemblies & components.

S/4HANA includes the embedded PEO and we won’t address alternative deployment options in this article.

Production Engineering and Operations for Complex Assembly (PEO) | SAP Mfg Solutions

Production Engineering and Operations for Complex Assembly (PEO) | SAP Help Portal

SAP Digital Manufacturing

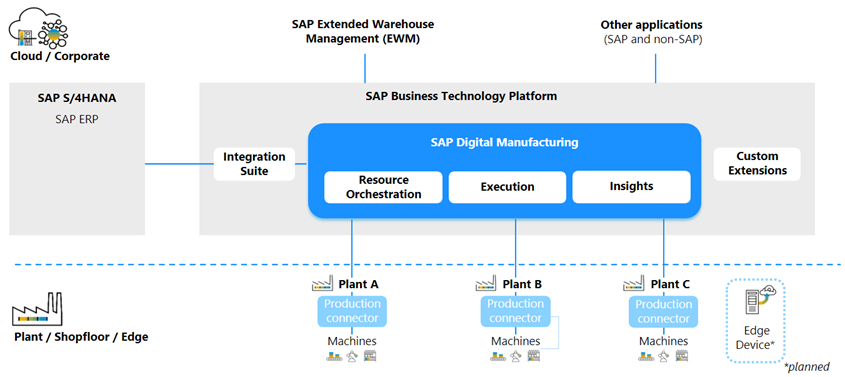

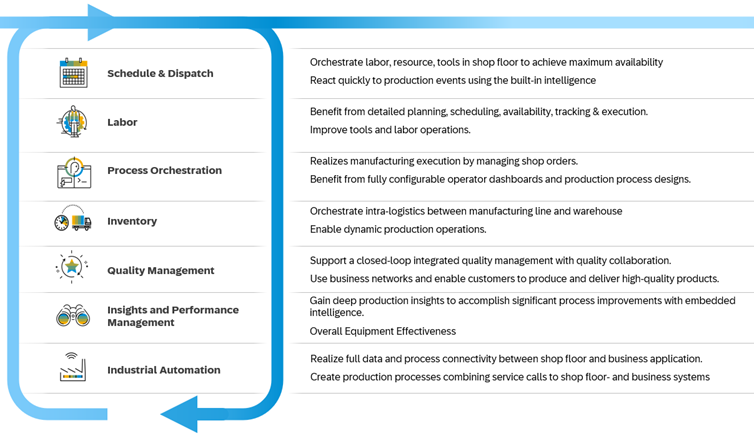

SAP Digital Manufacturing is a cloud-based manufacturing execution system (MES) supporting shop floor control, resource orchestration, intelligent factory operations and insights. Using SAP Digital Manufacturing for execution, you can monitor the entire manufacturing process to optimize resources and execution. Use role-specific SAP Fiori and operator dashboards and a configurable Production Operator Dashboard (POD) to orchestrate and control the shop floor, monitor overall equipment effectiveness (OEE), and manage downtime events. Automation interfaces provide for shop-floor-driven manufacturing events and data collection. Out-of-the box integration to SAP ERP, SAP S/4HANA, SAP Extended Warehouse Management (EWM), and SAP Business Network Asset Collaboration) enables seamless integration scenarios. It provides connectivity to retrieve machine data and to communicate with shop floor systems and Edge device.

High Level Architecture

Key capabilities of SAP Digital Manufacturing

Criteria to determine the most suitable target solution

Based on the characterization of the solution options this is mainly a buying decision where budget and costs must be compared with the benefits of adding SAP Digital Manufacturing to the target architecture. We assume that SAP S/4HANA is part of the target application architecture - the customer already running SAP S/4HANA or planning the transformation to S/4HANA.

Questions that can provide some orientation from MOM perspective.

- Is cloud deployment an option for a manufacturing execution system?

SAP Digital Manufacturing may not be an option due to regulatory restrictions (e.g., A&D environment). SAP DM is deployed on SAP BTP and operated as a software-as-a-service. For data center availability please refer to Supported Data Centers | SAP Help Portal - Does customer have any MES/MOM system?

If a non-SAP MES system is already in place to support manufacturing operations, and customer intends to keep the solution, then the architecture design needs to focus on the integration between the MES and S/4HANA.

Customer should consider SAP Digital Manufacturing in case they don’t have an MES and recognize the need of a digital solution to support manufacturing operations.

- Does customer run SAP ME?

The maintenance of SAP ME will expire and there are no plans for further releases, future innovations are focusing on SAP Digital Manufacturing as a key component of SAP’s strategic manufacturing solution portfolio. Customers running SAP ME are encouraged to plan the transformation to DM. - Does the customer require capabilities and features S/4HANA doesn’t have?

SAP Digital Manufacturing offers specific capabilities like manufacturing automation, data collection and Production Operator Dashboard (POD) to name a few. In general, SAP DM is best equipped to integrate with the shop floor control (SFC) systems and devices. - Is Edge computing required?

SAP S/4HANA doesn’t provide edge computing component. Using SAP Digital Manufacturing for edge computing, you can process machine data, and thereby support production processes, closer to the source of data and on the shop floor, to enable faster decision-making and to operate with latent connectivity to the cloud. SAP Digital Manufacturing for edge computing enables you to deploy a defined set of functions provided by SAP Digital Manufacturing on the edge.

SAP Digital Manufacturing for edge computing enables the synchronization of configuration and business data between edge and cloud. The solution also provides a graphical user interface that allows you to access functions on the edge. - What is the manufacturing environment?

For complex ETO and CTO+, CTO assembly processes, particularly in industries like Industrial Manufacturing, Machinery, and Components (IM&C) or Aerospace and Defense (A&D), the SAP PEO is a suitable alternative compared to SAP Digital Manufacturing.

Conclusion

Companies using SAP have been running Production Control in their ERP solution and moving to S/4HANA they can continue to do so. While SAP S/4HANA has the standard core MOM capabilities, customers recognize the need for more robust digital solution to manage manufacturing operations close to the SFC.

According to the characteristics and capabilities of the solutions SAP S/4HANA with SAP Digital Manufacturing is a recommended target application landscape while S/4HANA with PEO is more suitable for specific industries with complex manufacturing environment.

- SAP Managed Tags:

- SAP Digital Manufacturing,

- SAP S/4HANA