- SAP Community

- Groups

- Interest Groups

- Enterprise Architecture

- Knowledge Base

- Solution Options for Material Requirements Plannin...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

- Document History

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

on 12-20-2023 6:55 PM

Summary

This article describes alternative options of an SAP application landscape that can provide Material Requirements Planning (MRP) capability. A list of questions is intended to help evaluating the options and to make the right choice for a customer, taking their situation and preferences into account.

Business Requirements

Material Requirements Planning (MRP) is designed to plan material requirements primarily for manufacturing production to meet market demand. It identifies necessary materials, estimates quantities, determines when materials will be required to meet the production schedule and manages delivery timing.

MRP calculates net requirements, proposed quantities and dates to cover the requirements. This typically includes planning (exploding) the bill of materials (BOM), creating purchasing recommendations, and providing operational plan proposals by taking lead times or routing information into account for requirement date calculation.

The main function of material requirements planning is to guarantee material availability, that is to procure or produce the requirement quantities on time both for internal purposes and for sales and distribution. This process involves the monitoring of stocks and the automatic creation of proposals for purchasing and production.

Solution Options

MRP functionality is available in many major ERP systems. SAP has two solutions that provide MRP capabilities:

- SAP S/4HANA

- SAP Integrated Business Planning

In the context of MRP the question is not either/or – the two solutions are not mutually exclusive. While the primary solution for MRP is the core SAP S/4HANA, the planning capabilities can be extended with SAP Integrated Business Planning (IBP). In the case of IBP, the decision is how the two systems can work together in the MRP process.

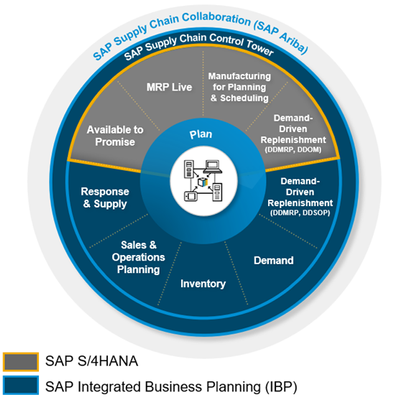

SAP S/4HANA and IBP in the context of Supply Chain Planning (Figure 1) - both are part of SAP’s overall Supply Chain Planning solution and provide out of the box standard integration to enable end-to-end process capabilities.

Figure 1 – Supply Chain Planning in the Intelligent Enterprise

Characterization of the Solution Options

The brief description below focuses on the MRP context only and is not intended to provide the full scope of the capabilities of the products.

SAP S/4HANA

SAP S/4HANA has all the standard MRP capabilities to execute and evaluate both demand (forecast) based and consumption-based planning. The following MRP procedures are available in S/4HANA:

- Material Requirements Planning

- Master Production Scheduling

- Consumption-based Planning

- Demand-Driven Replenishment

In S/4HANA the planning run can be carried out using MRP Live or Classic MRP (like in previous SAP ERP solutions). The default and recommended execution option is MRP Live. Using MRP Live, you can benefit from improved performance and execute the planning run in much shorter cycles, even several planning runs daily.

For more details visit Material Requirements Planning (PP-MRP) | SAP Help Portal

SAP Integrated Business Planning

SAP IBP doesn’t have MRP specifically identified as a functionality – the capability is embedded in IBP Sales and Operations Planning (S&OP) and particularly in IBP Response & Supply (Supply Response Planning) in form of planning algorithms. Beyond the ability of unconstrained heuristic (like classic MRP with no capacity constraints) IBP provides more sophisticated planning capabilities with the ability to execute constraint-based heuristics and optimization algorithms as well as simulations.

SAP IBP is a robust supply chain planning solution with the following feature areas:

- Demand forecasting and management

- Inventory planning and optimization

- Sales and operations planning (S&OP)

- Response and supply planning

For further details on the various IBP solution capabilities visit SAP IBP | Integrated Business Planning Software for Supply Chain

Integration Scenarios

As mentioned above the two solutions are not mutually exclusive. Out-of-the-box integration between IBP and S/4HANA enables seamless planning integration and synchronization between planning and operational execution. Note that SAP IBP solution can be integrated with different SAP and non-SAP products for different purposes, so master data and transactional data can be exchanged (SAP IBP Data Integration Scenarios).

Sample integration scenarios

- IBP Demand integrating Forecast as input to S/4HANA MRP Live

- IBP Inventory Optimization integrating stock levels as input to S/4HANA MRP Live

- IBP Inventory Optimization integrating stock levels as input to S/4HANA MP&S

- IBP Response & Supply integrating the tactical plan as guard rails (constraints) to S/4HANA MP&S

- IBP DDMRP integrating buffer definitions as input to DDMRP Planning and Execution in S/4HANA DDMRP

As an example, you can execute the planning in IBP at the finished goods level and transfer planned orders (or other MRP elements) to S/4HANA and run plant/MRP-area level MRP to explode multi-level BOMs, planning lower levels not in IBP.

Cross system MRP

SAP IBP can integrate with multiple ERPs, e.g., a single global IBP with regional SAP ERP systems. Another use case is a rather complex scenario when customer runs separate, independent ERPs for their factories (each physical factory as an entity runs their own ERP system for production planning and execution). In this scenario the plants run their own MRP while need to manage demand and product availability across the sites. E.g., finished goods are manufactured in a plant, but components, assemblies are coming from other plants. It is also possible that multiple plants produce the same material (finished or component) and supply the same finished good or assembly manufacturing or supply different distribution channels. SAP S/4HANA supports cross-plant planning to carry out MRP for various plants centrally, however when the plants are in separate systems, it would be a rather complicated process. SAP IBP could provide central visibility of the product demand and support cross site supply planning while integrating with the individual ERPs.

Determining the right solution and process mix is not the scope of this article. It would depend on the specific customer scenario(s) and requires adequate analysis and solution design based on expertise from both S/4HANA and IBP.

Criteria to determine the most suitable target solution

Based on the characterization of the solution options this is mainly a buying decision where budget and costs must be compared with the benefits of adding SAP Integrated Business Planning to the target architecture. The decision goes beyond the simple MRP functionality and would assess SAP IBP as a comprehensive supply chain planning solution.

Some question that can provide some orientation from MRP perspective:

- Does the current ERP solution have MRP capabilities? Does the business need more MRP functionality than the current ERP can provide?

If the existing ERP system (non-SAP) doesn’t have sufficient MRP capabilities, SAP IBP is an alternative. IBP would especially be the right choice if the customer doesn’t have other supply chain planning solution at all. - Is there a negative business impact from lack of comprehensive supply and response planning?

Does the customer have to deal with large number of backorders, delayed shipments, etc.? While the main function of MRP is to guarantee material availability, the lack of adequate supply plan of the finished products can lead to unplanned shortages of components, parts required, ultimately delaying the fulfillment of actual orders. SAP IBP can extend the basic MRP with integrated supply planning capabilities. - Can the customer respond to dynamic demand changes quickly and accurately?

S/4HANA MRP Live enables the planning run in much shorter cycles, even several planning runs daily. However, with no appropriate input from demand changes the requirements calculation will not adjust the plan. - Does SAP IBP offer specific MRP features not available in SAP ERP?

Evaluate the additional MRP relevant features of SAP IBP Response & Supply. - Does the customer rely on SAP APO for their supply chain planning?

The standard maintenance for SAP APO will expire by end of 2027. Customers running SAP APO encouraged to move to SAP IBP.

Conclusion

Companies using SAP have been running MRP in their ERP solution and moving to S/4HANA they can continue to do so. While SAP S/4HANA has all the standard MRP capabilities, customers recognize the need for more robust supply chain planning solution. In the context of Material Requirements Planning SAP IBP extends the core SAP S/4HANA capabilities with network centric approach and sophisticated planning algorithms.

SAP IBP is a robust supply chain planning system and shouldn’t be considered for MRP only. Based on the various integration scenarios customers can adopt end-to-end planning processes specific to their needs by leveraging both S/4HANA and IBP.