- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- S/4HANA Embedded Extended Warehouse Management (EW...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Introduction

This blog continuation to previous one – S/4HANA Embedded Extended Warehouse Management (EWM) Advanced Production Integration Configuration

Advanced production integration allows you to integrate the supply of products to production and the receipt of products from production into your warehouse in S/4HANA Embedded Extended Warehouse Management (EWM). It is integrated with the manufacturing order processing in SAP S/4HANA and allows you to stage and consume the materials and receive the semi-finished products or finished products in S/4HANA Embedded EWM.

The warehouse execution for the SAP S/4HANA Production Orders is based on the Production Material Request (PMR) document.

Process Flow

The overall process flow as describes in the below image.

Master Data

The following master data elements to be created.

- Business Partner

- Production Supply Area

- Control Cycle

- Replicate Production Supply Area to EWM

- Assign Bin to PSA/Product/Entitled in Warehouse Number

- Material Master

- Bill of Material

- Work Center

- Routing

- Production Version

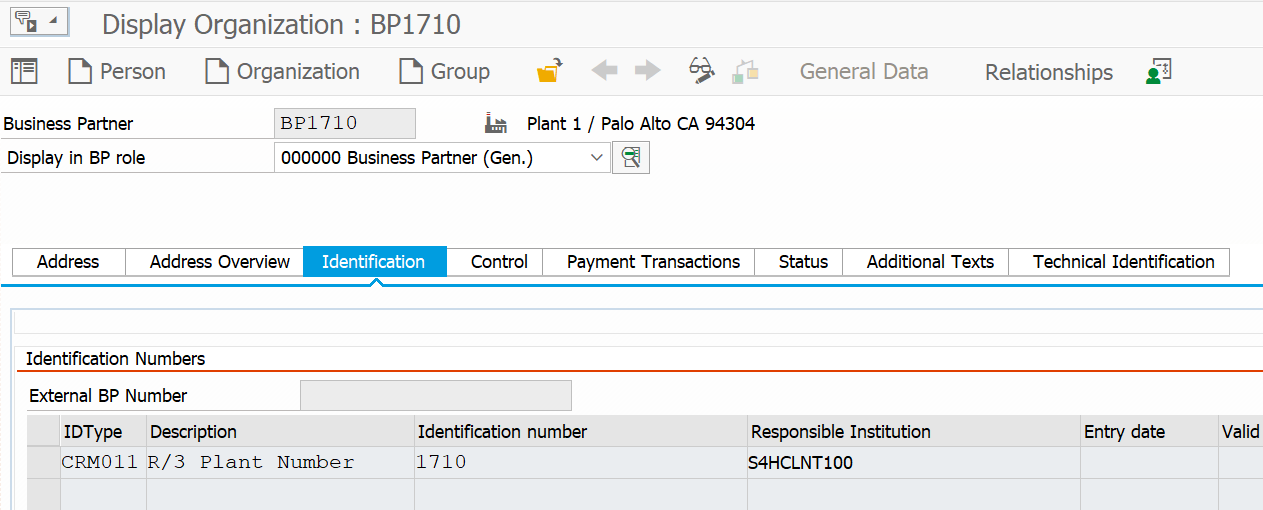

Maintain Business Partner

Business partners are parties in which your company has a business interest. You can create and manage your business partners centrally for different business transactions and indicate the different roles they play, such as sold-to party and ship-to party.

Easy Access Menu (SAP EWM) | SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Maintain Business Partner |

| Transaction Code | BP |

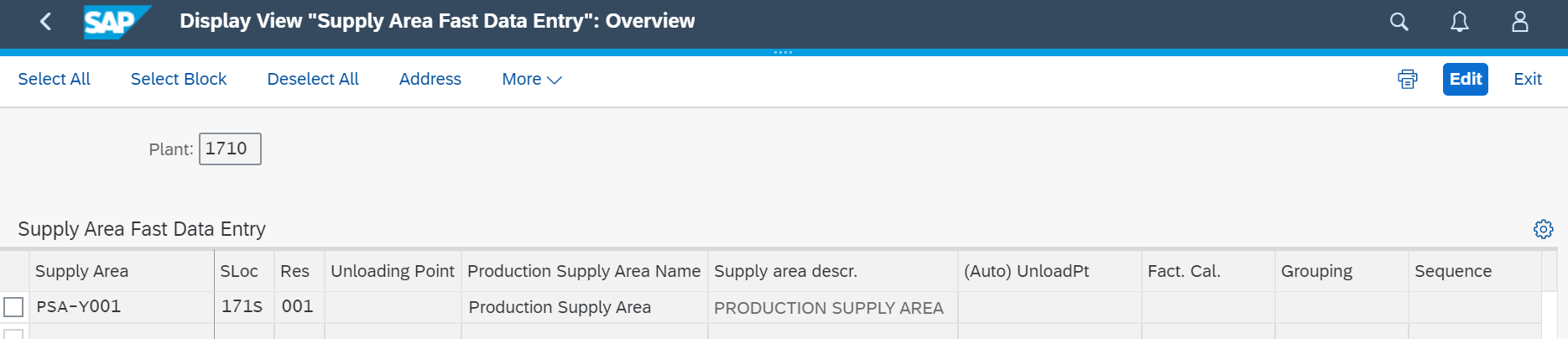

Production Supply Area

An area in production or in the warehouse where products are staged or withdrawn.

To stage products for a manufacturing order, a warehouse must know where it has to take the products. For manufacturing orders in the SAP S/4HANA system, the PSA contains this information.

A PSA usually contains one or more storage bins where you can stage the products of a manufacturing order. For this reason, the EWM system needs information about the PSAs to find out the correct storage bin for staging the products, depending on the following:

Product number

Party entitled to dispose

GUI transaction code - PK05

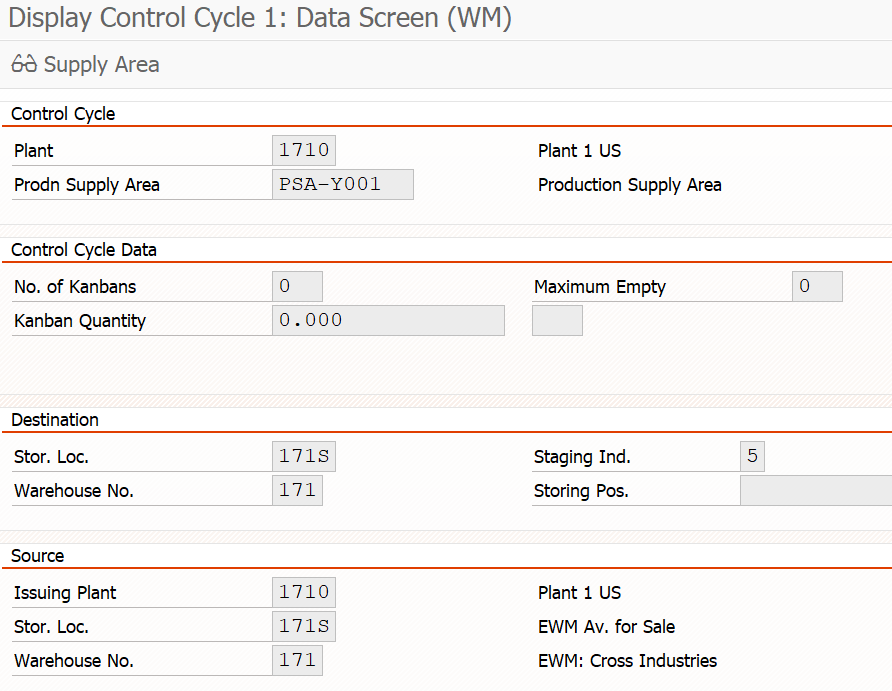

Control Cycle

With the EWM control cycle, you specify the EWM-managed storage location from which the material required for production is to be withdrawn and the production supply area in which this material is to be staged. In addition, you specify the staging type (such as Release Order Part

or Crate Part

).

The following control cycle categories are possible in conjunction with SAP-EWM:

Control cycle for EWM

This

Control Cycle Category

indicates that the source and destination that you specify in the control cycle are EWM-managed. You can use this control cycle category for production and process orders only.

GUI transaction code - LPK3

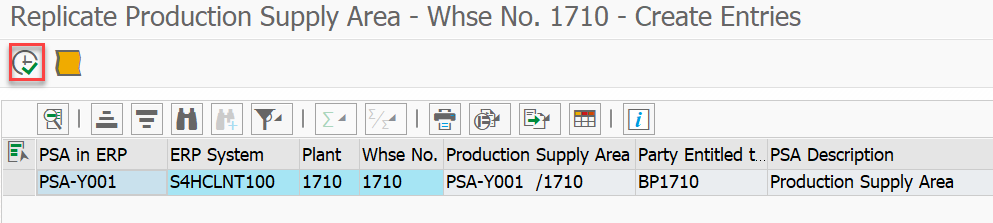

Replicate Production Supply Area to EWM

You can replicate PSAs from the SAP S/4HANA EWM system source and destination in one system.

Easy Access Menu (SAP EWM) | SCM Extended Warehouse Management → Extended Warehouse Management → Interfaces → ERP Integration → Replicate Production Supply Area (PSA) |

| Transaction Code | /SCWM/PSA_REPLICATE |

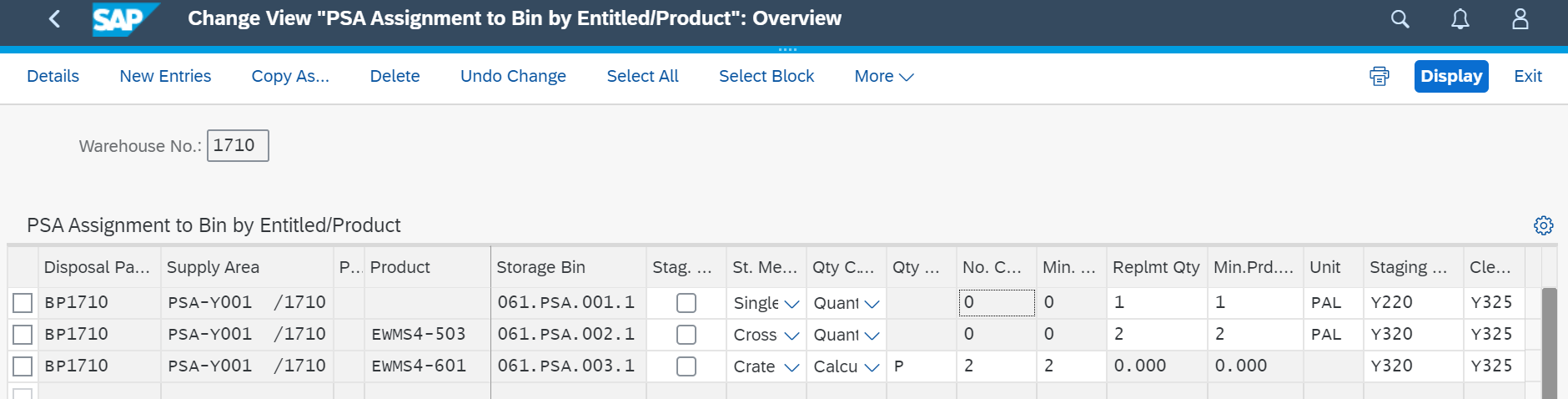

Assign Bin to PSA/Product/Entitled in Warehouse Number

ou do not assign a storage bin to a production supply area (PSA) directly, instead you define the storage bin in which you want to stage a particular product or product group within a PSA. By making this assignment, you define the following:

- Determination of the storage bin for staging to the PSA

- Determination of the storage bin for the consumption of products from the PSA

- Determination of the storage bin for the physical inventory in the PSA

Easy Access Menu (SAP EWM) | SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Production Supply Area (PSA) → Assign Bin to PSA/Product/Entitled in Warehouse Number |

| Transaction Code | /SCWM/PSASTAGE |

Material Master

The material master contains information on all the materials that a company procures or produces, stores, and sells. It is the company's central source for retrieving material-specific data. This information is stored in individual material master records.

GUI transaction code - MM03

| Plant | Value | UoM | Description |

| 1710 | EWM-50 | 1 PAL = 6 EA | FIN50,Fast Moving |

| 1710 | EWM-501 | 1 PAL = 6 EA | RAW501,Fast Moving |

| 1710 | EWM-502 | 1 PAL = 8 CAR = 48 EA | RAW502,Fast Moving |

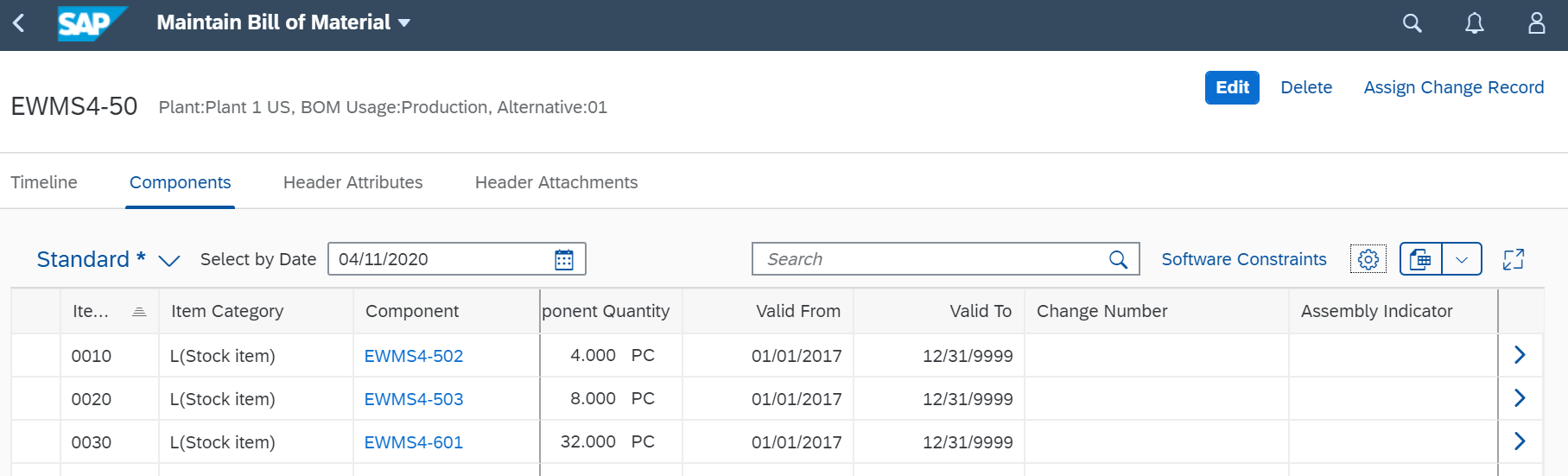

Bill of Material

A formally structured list of the components that make up a product or assembly. The list contains the object number of each component, together with the quantity and unit of measure.

BOMs are used in their different forms in various situations where a finished product is assembled from several component parts or materials. Depending on the industry sector, they can also be called recipes or lists of ingredients and so on.

GUI transaction code - CS03

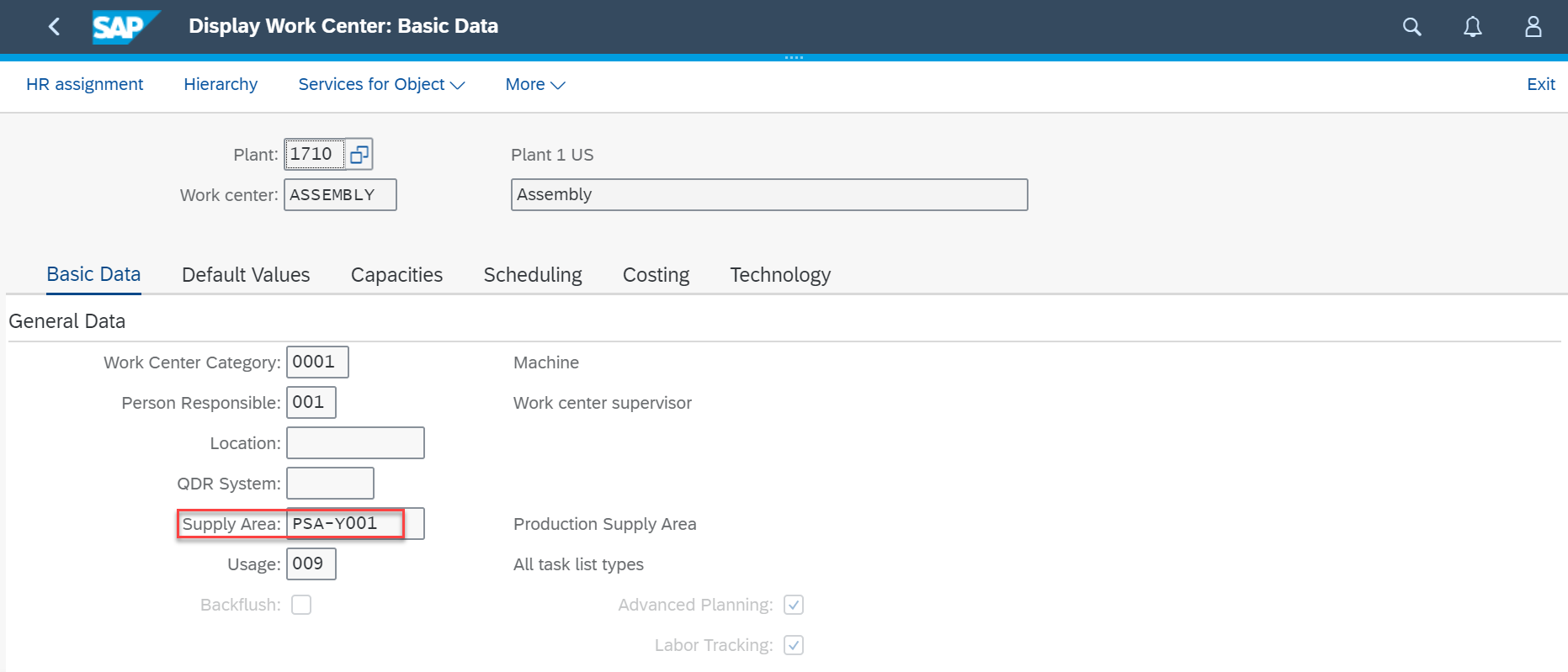

Work Centers

Operations are carried out at a work center. In the SAP system work centers are business objects that can represent the following real work centers, for example:

- Machines, machine groups

- Production lines

- Assembly work centers

GUI transaction code - CR03

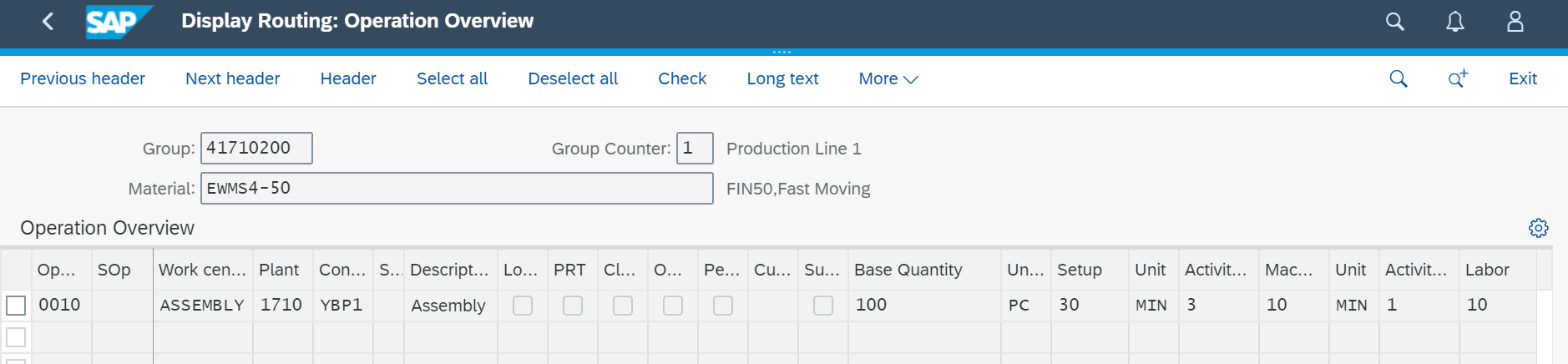

Routing

Routings enable you to plan the production of materials (products). Therefore, routings are used as a template for production orders and run schedules as well as a basis for product costing.

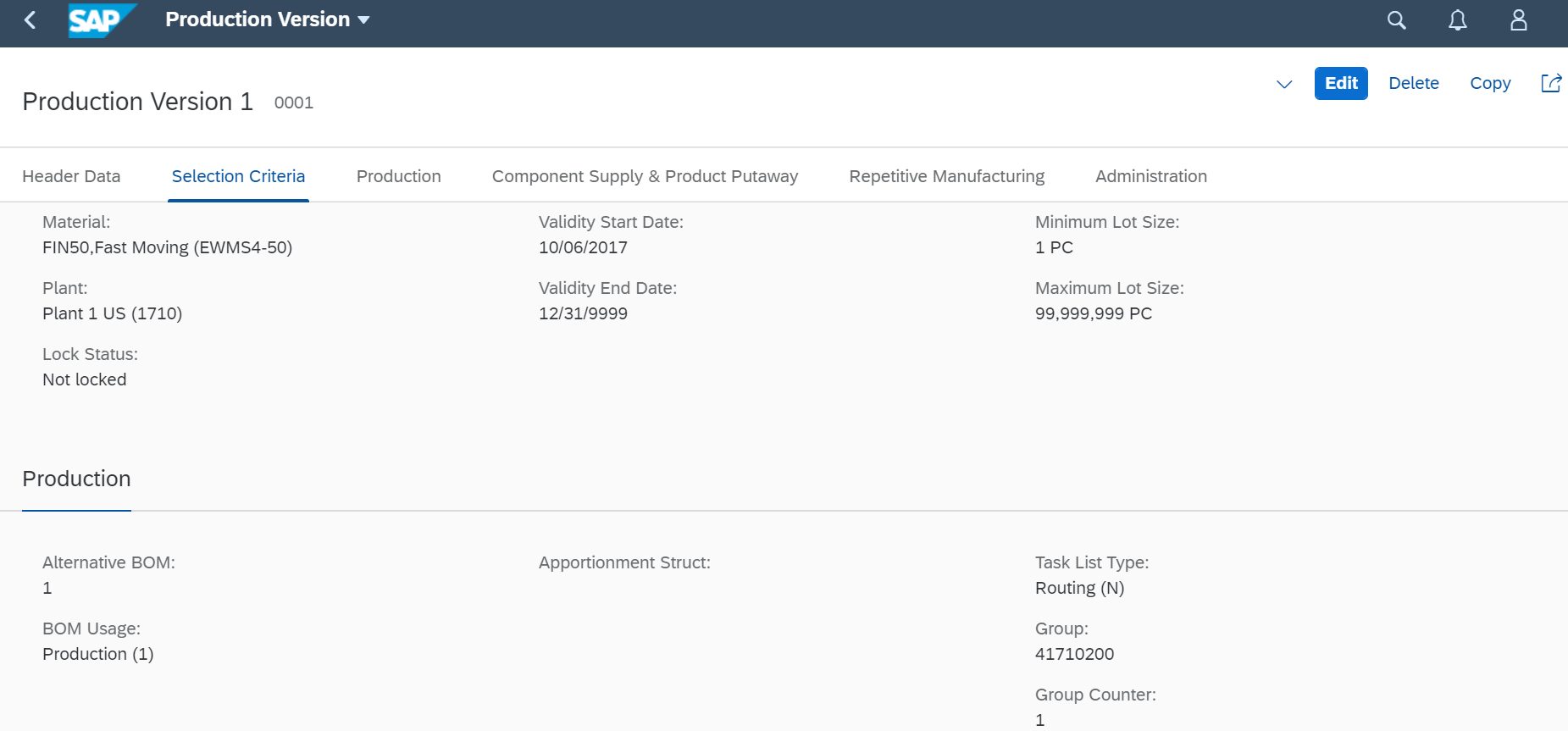

Production Version

The production version defines the various techniques that can be used to produce a material.

A material may have several bills of material (BOMs) that determine the components used in its production. The production process can also be described in various routings. Data on the different methods or techniques used to produce a material is recorded in production versions which are assigned to the material.

A material can have one or more production versions. Data relating to individual production versions is located at plant level. You are free to define production version numbers as you see fit; however, each number must be uniquely identifiable.

GUI transaction code - C223

Process Steps

The following are the production execution steps for material staging.

- Creation of production order

- Release production order

- Review production material request (PMR)

- Material staging

- Process warehouse task and warehouse order

- Production consumption

- Production order goods movement review

- Production confirmation

- Production goods receipt

- Production order review

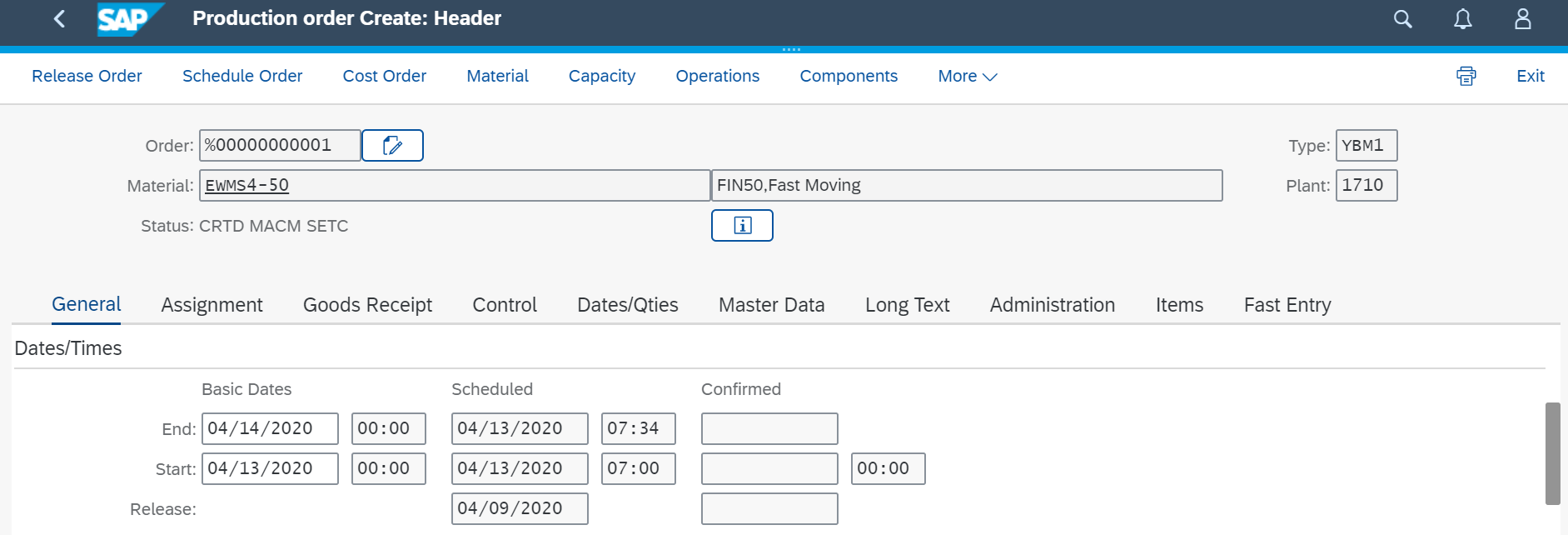

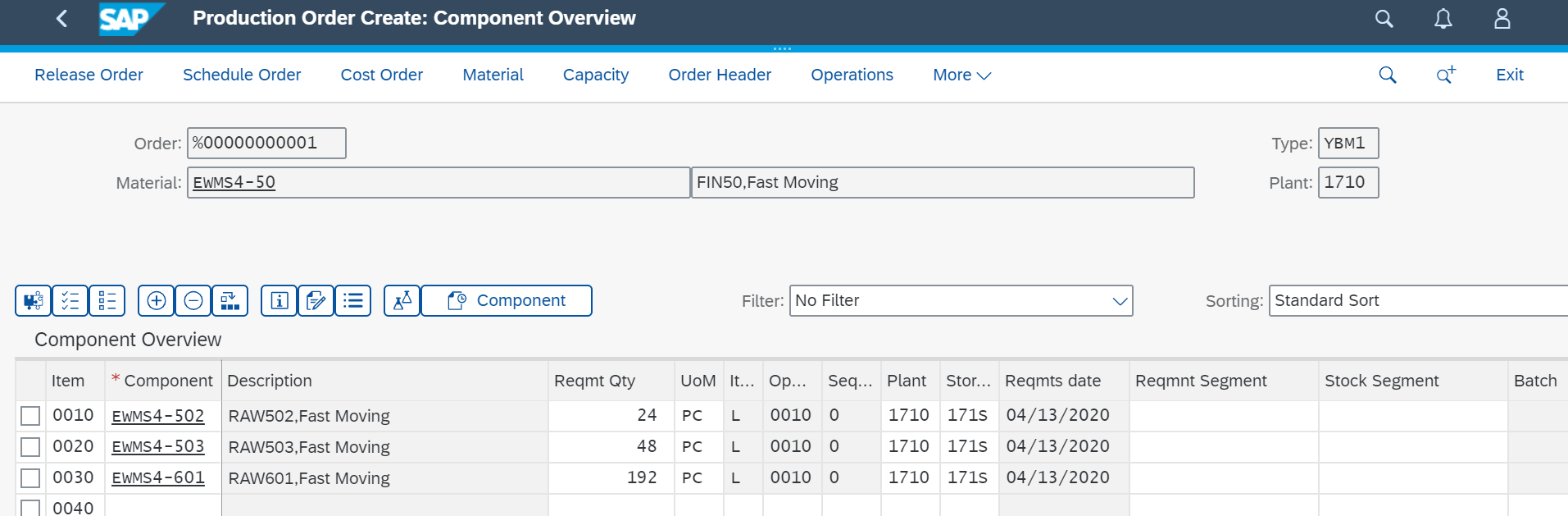

Creation of production order

Fiori App - Create Production Order

Production order created for EWMS4-50.

![]()

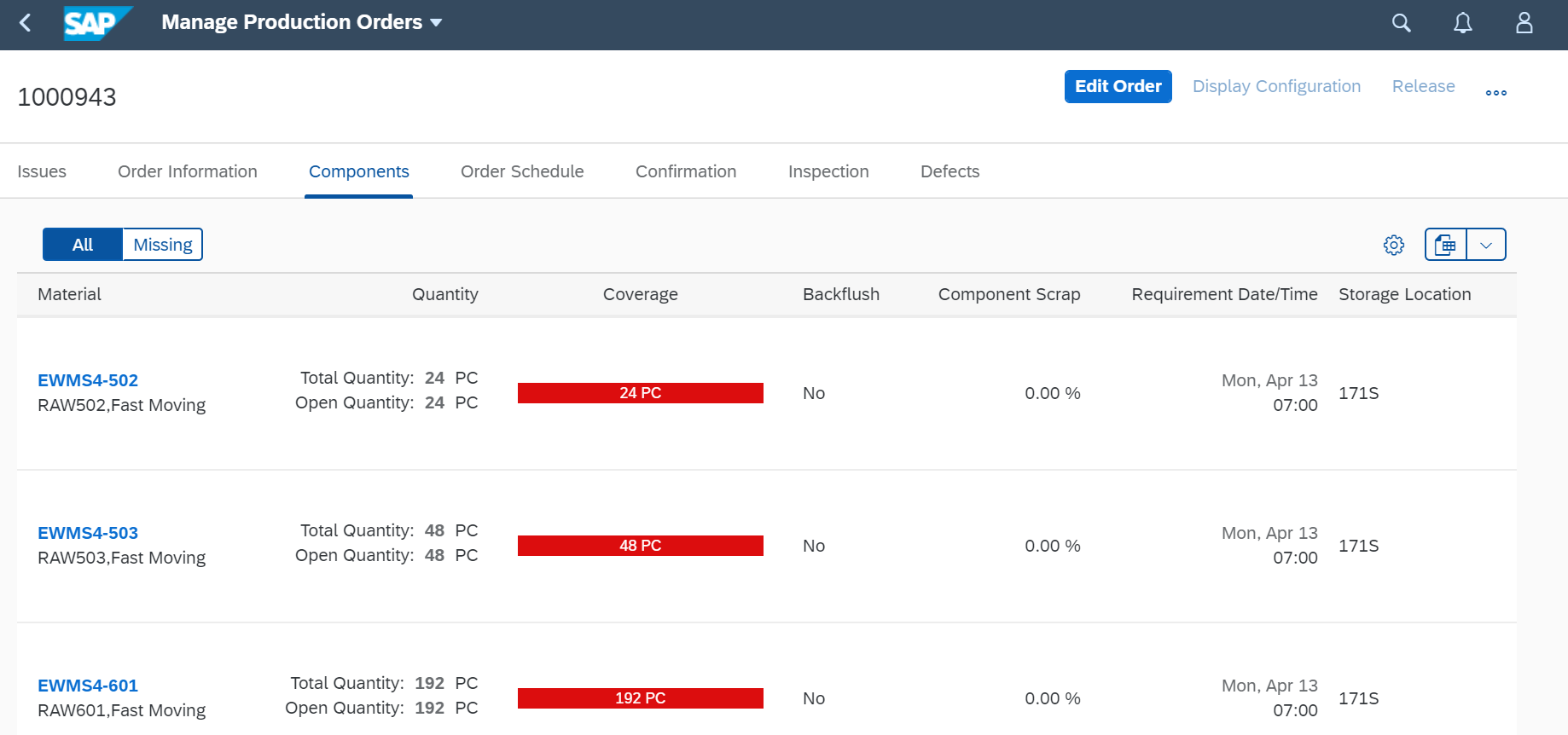

Release production order

Fiori App - Manage Production Orders

During production order release material staging will be executed and production material request created in S/4HANA and distributed to EWM within S/4HANA core.

Materials total and open quantity open processing.

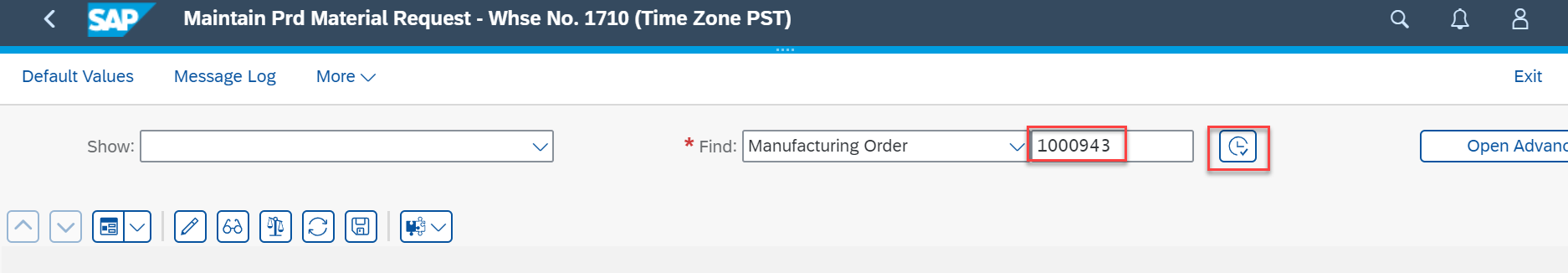

Review production material request (PMR)

Fiori App - Production Materials Request

Review the production material request # 1811 displayed with production order materials.

Manufacturing order status update in production material request based on material consumption and changes to production order.

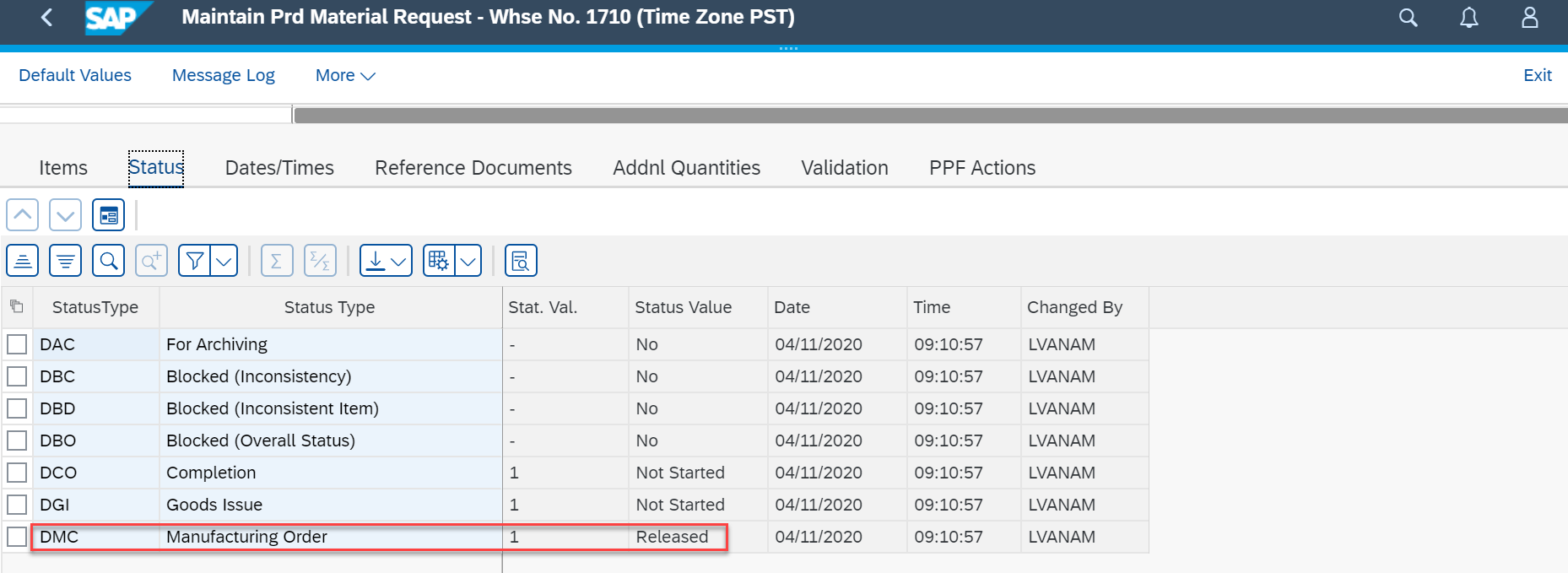

Material staging

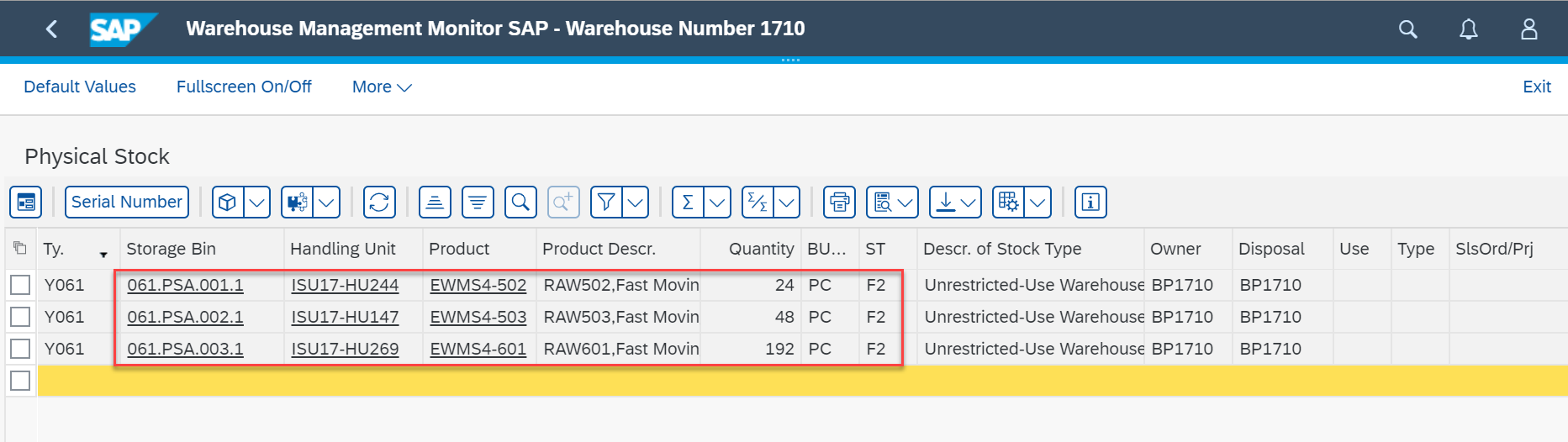

SAP Fiori App - Warehouse Monitor

Check physical stock in inventory before executing staging. In this scenario stock available in production supply area for two materials and remaining one material staging to be executed.

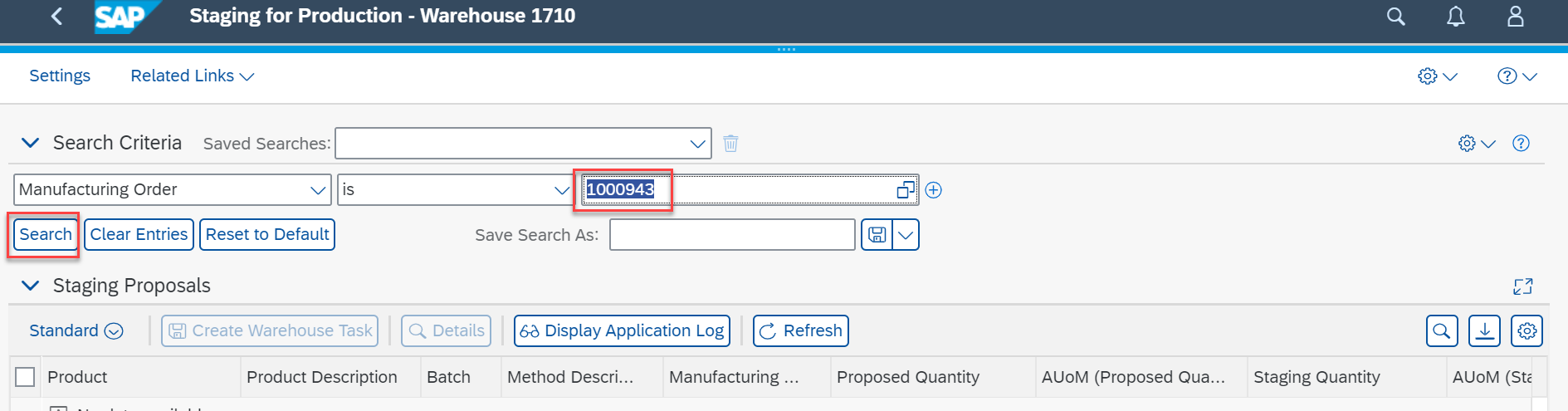

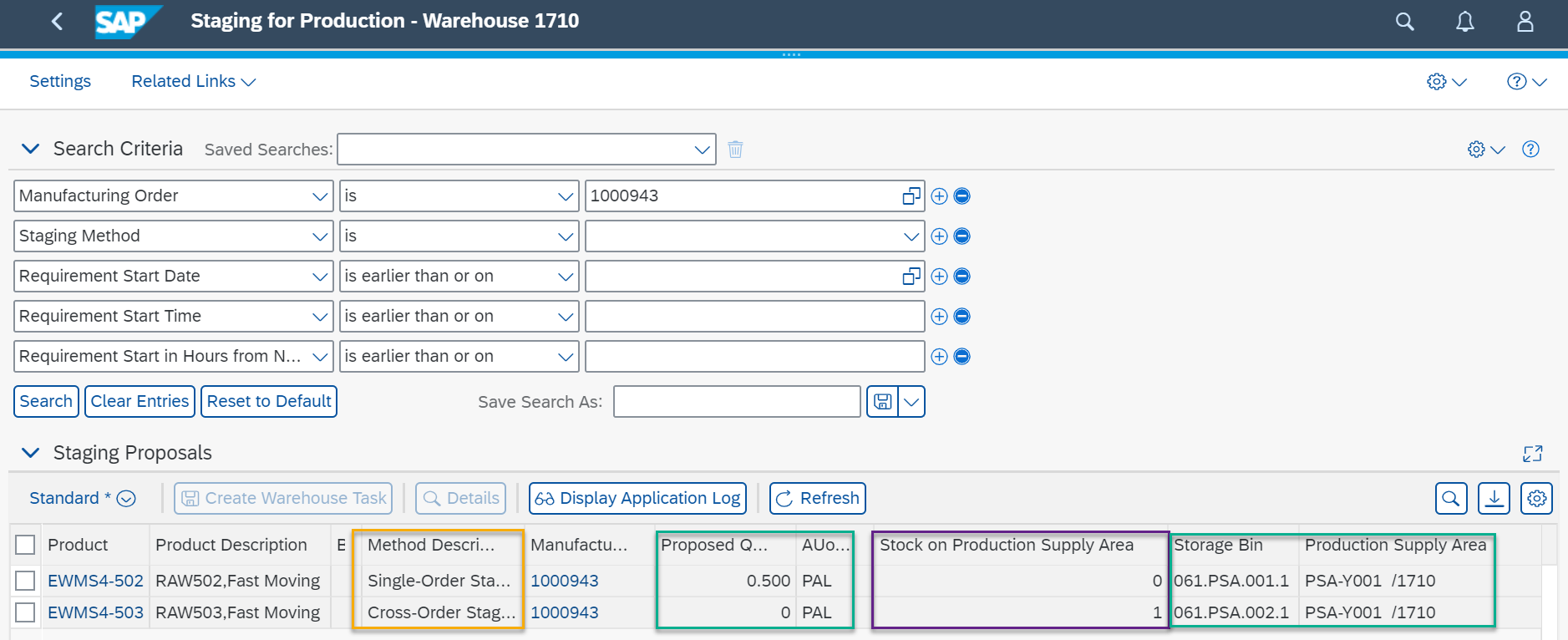

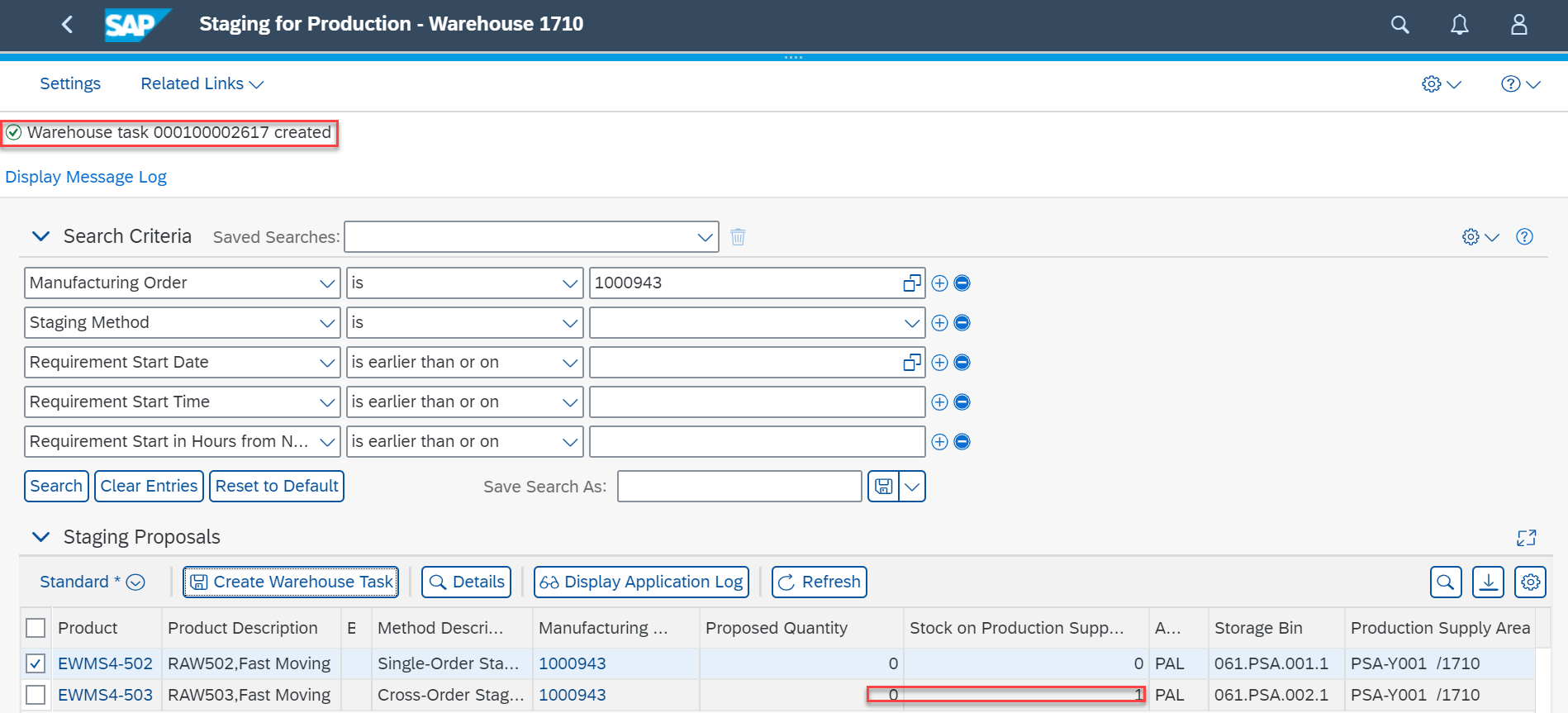

Fiori App - Stage for Production

Perform material staging for manufacturing order # 1000934.

In this scenario the following staging methods covered.

- Single order staging - Individual production order material request processed for manufacturing components.

- Cross-order staging - Multiple manufacturing orders components requests considered palnned based on required production quantities.

In the below example, material EWMS4-50 required 0.5 PAL - 24 PC, material EWMS4-503 1 PAL - 48 PC available tin production supply area. During staging material EWMS4-503 not planned due to stock availability in the production supply area.

Warehouse task # 100002617 created for EWMS4-502.

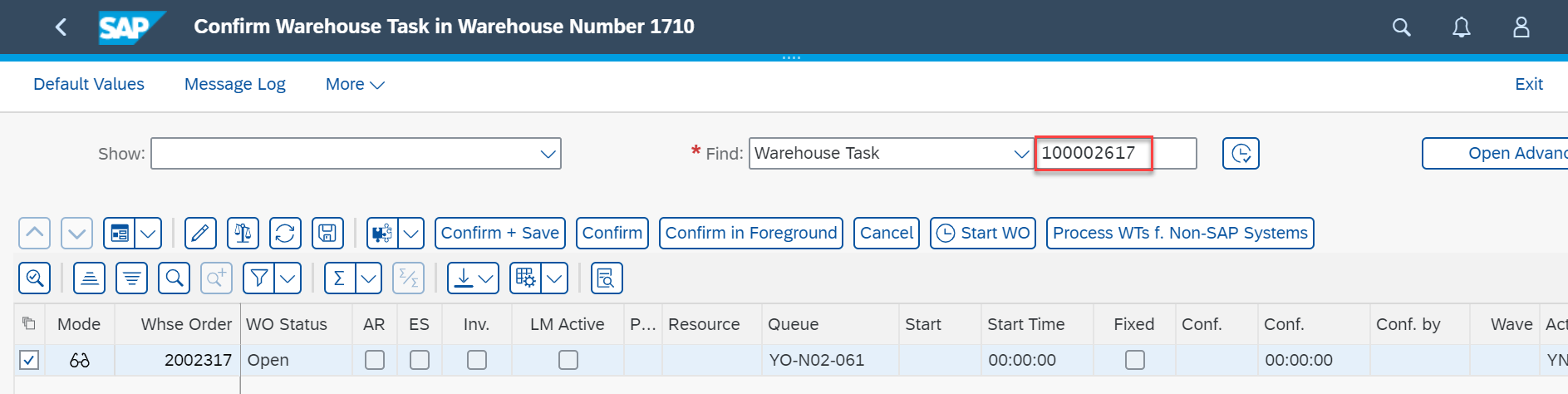

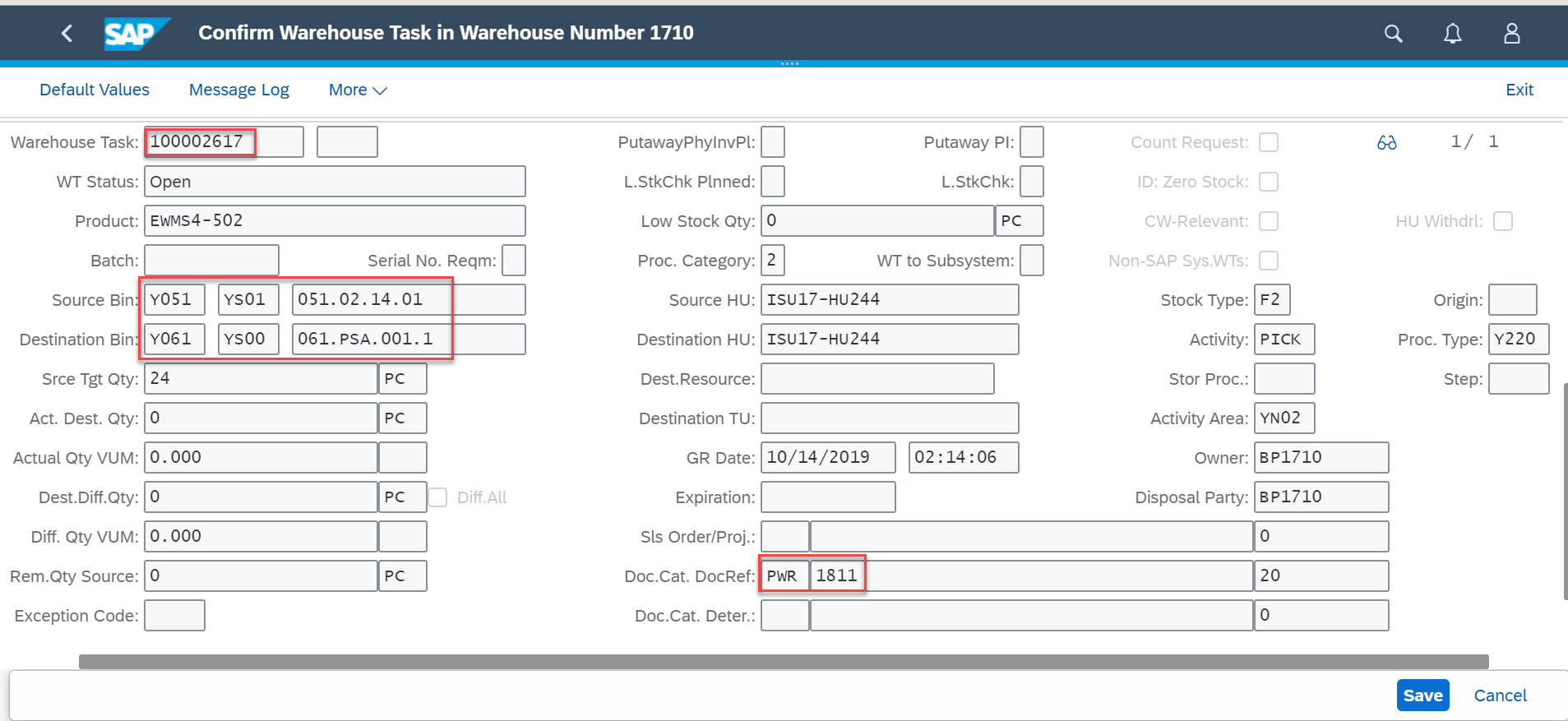

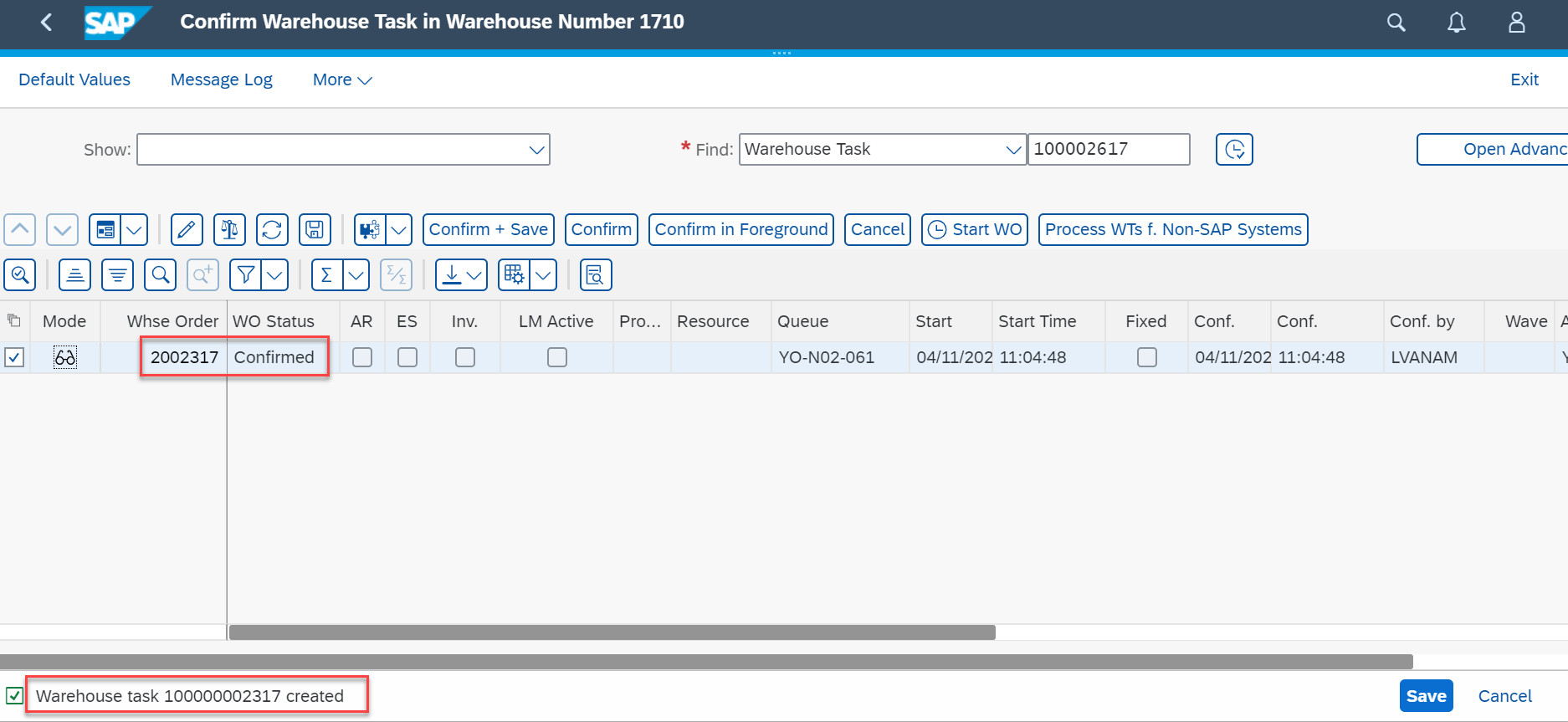

Warehouse task process

Fiori App - Confirm warehouse tasks

Process warehouse task # 100002617.

Warehouse order # 2002317 confirmed stock transferred to the warehouse to production supply area (PSA).

Warehouse task confirmed stock moved from warehouse bin to production supply area.

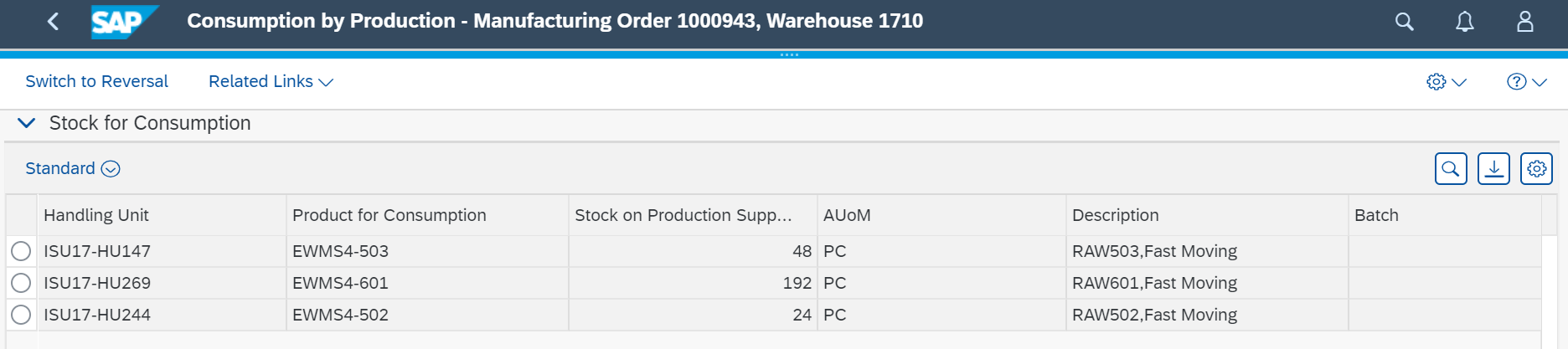

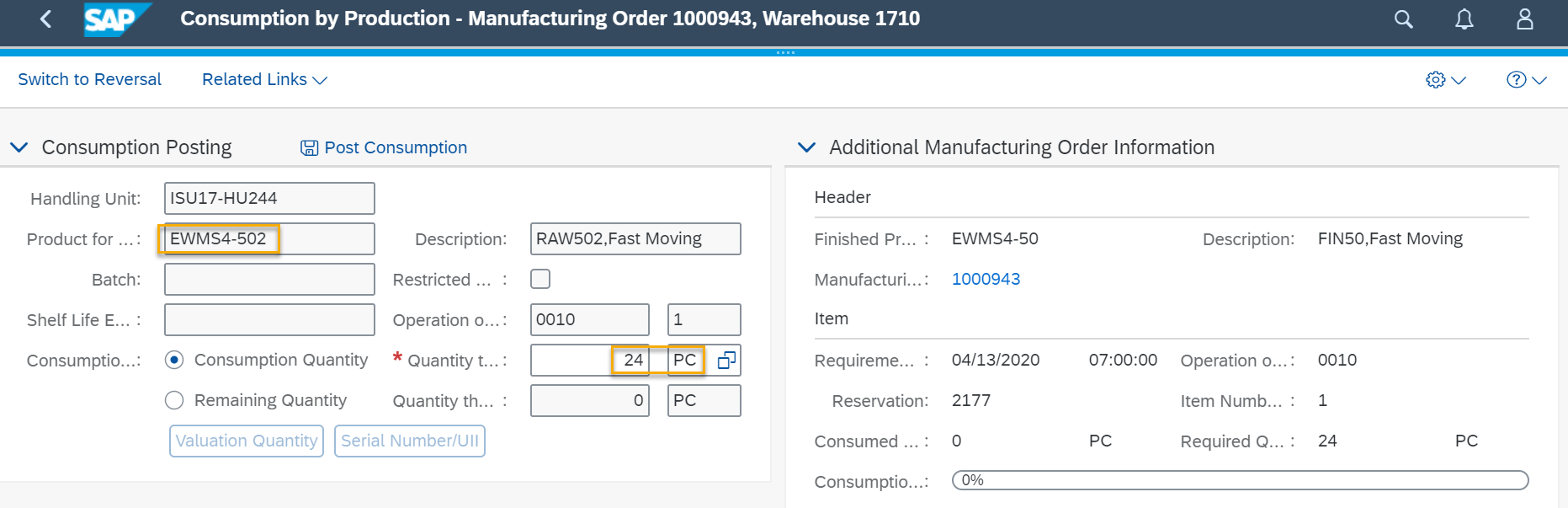

Production consumption

Fiori App - Post Consumption

Production operator consume materials during the shop floor execution. Material consumption can be process in the follwoing ways.

- Manual staging

- RF Device

- Backflush - S/4HANA Embedded EWM allows to post automatically backflush during warehouse task confirmation.

In this scenario, manual staging process considered.

Production operator manually select the required component and consume stocks from production supply area. Serial and batch numbers to be manually selected and post-consumption.

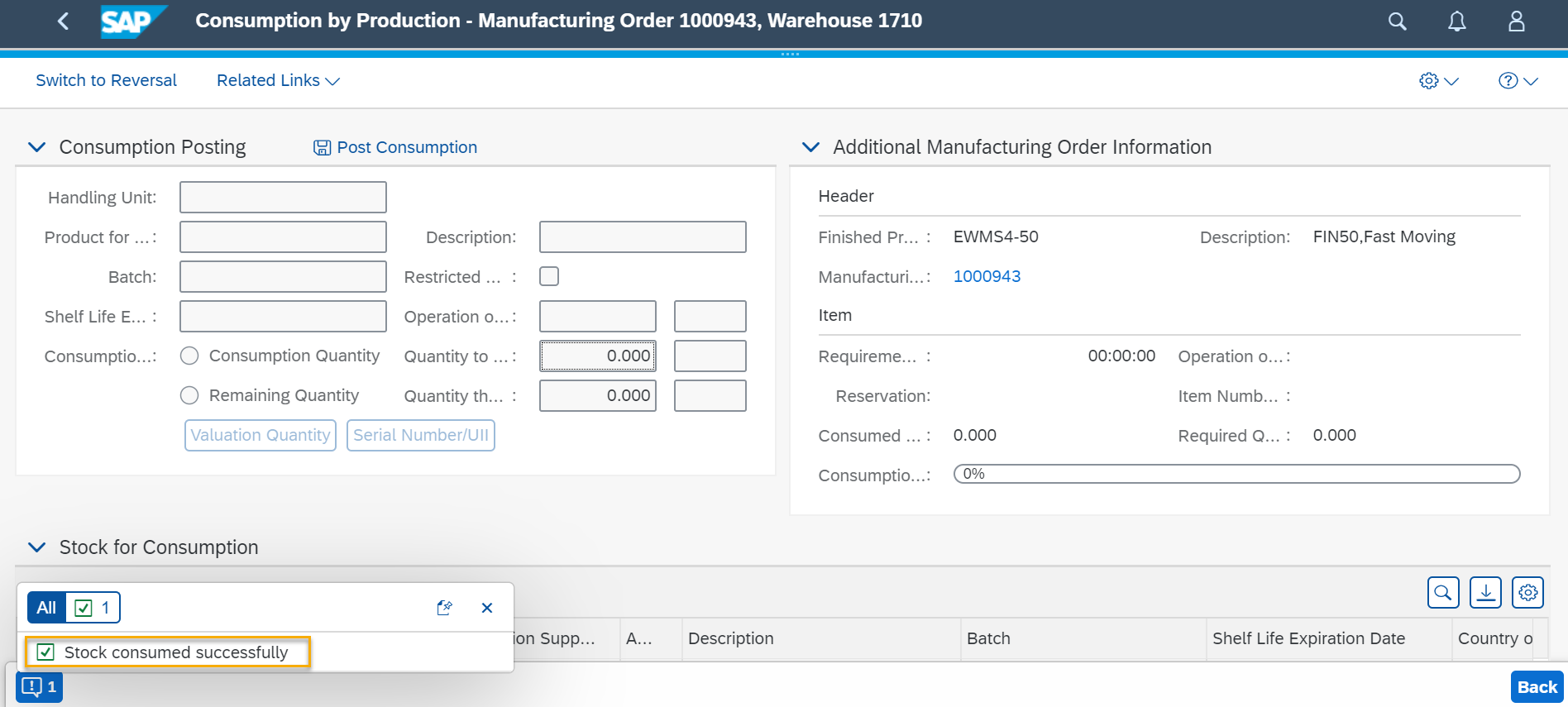

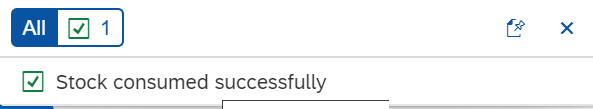

Stock consumed successfully and stock posting updated back to production order goods movements and material documents generated.

Production order goods movement review

Fiori App - Manage Production Orders

Material movements from warehouse consumption updated in manufacturing order automatically.

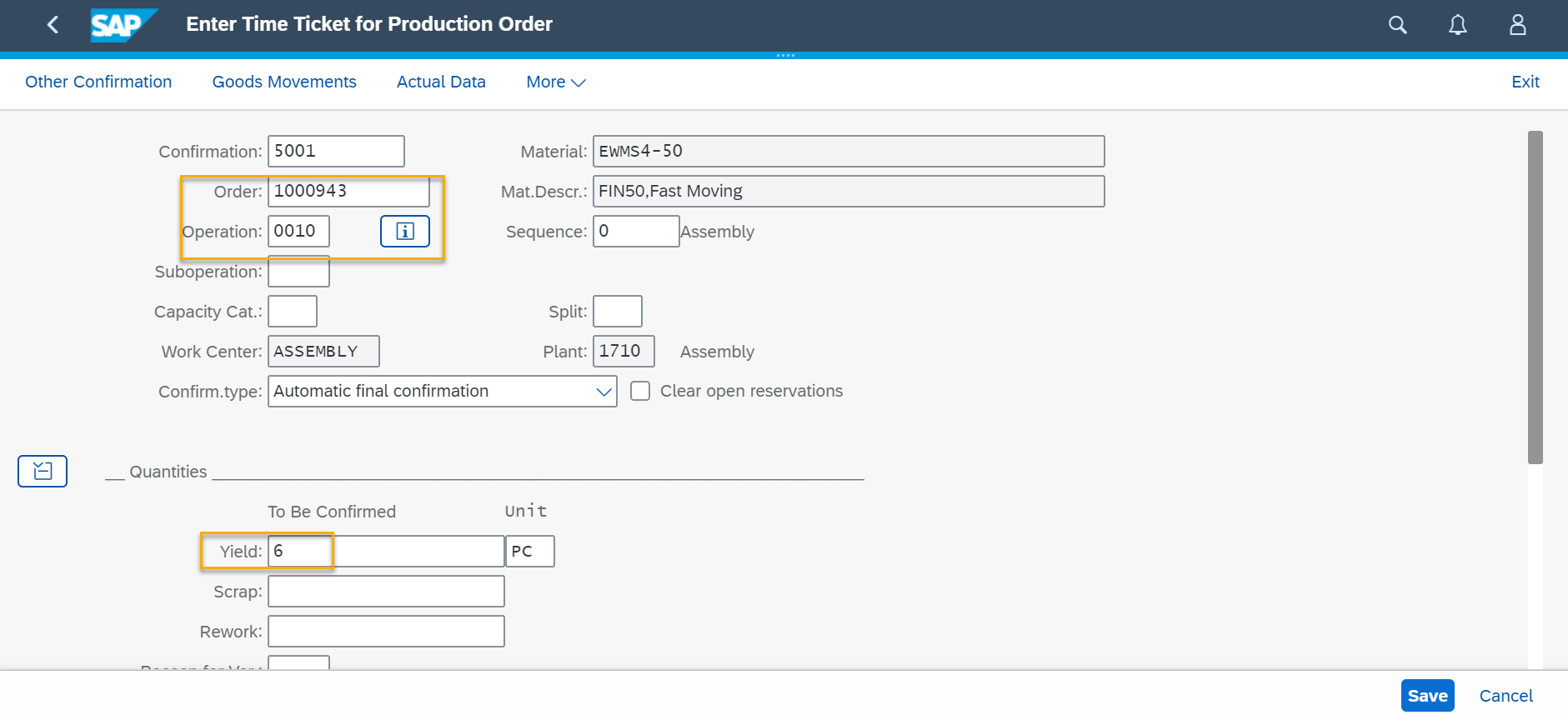

Production order confirmation

Fiori App - Confirm production operation

Production order # 1000943 confirmed successfully.

![]()

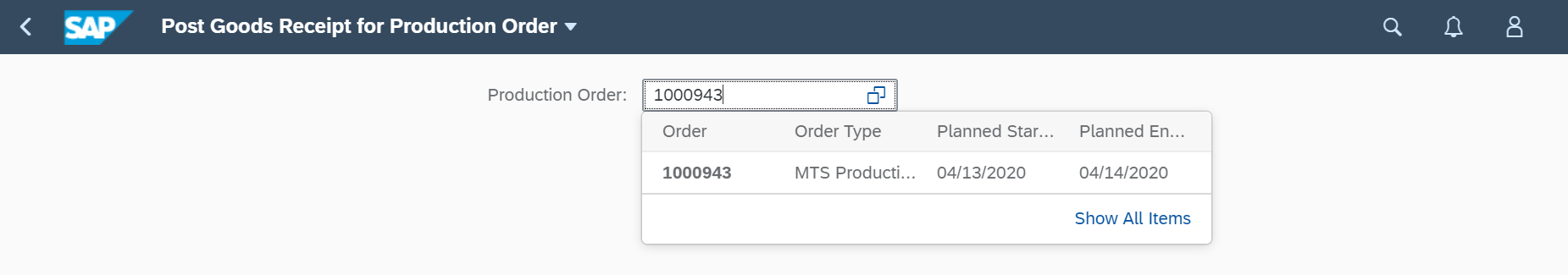

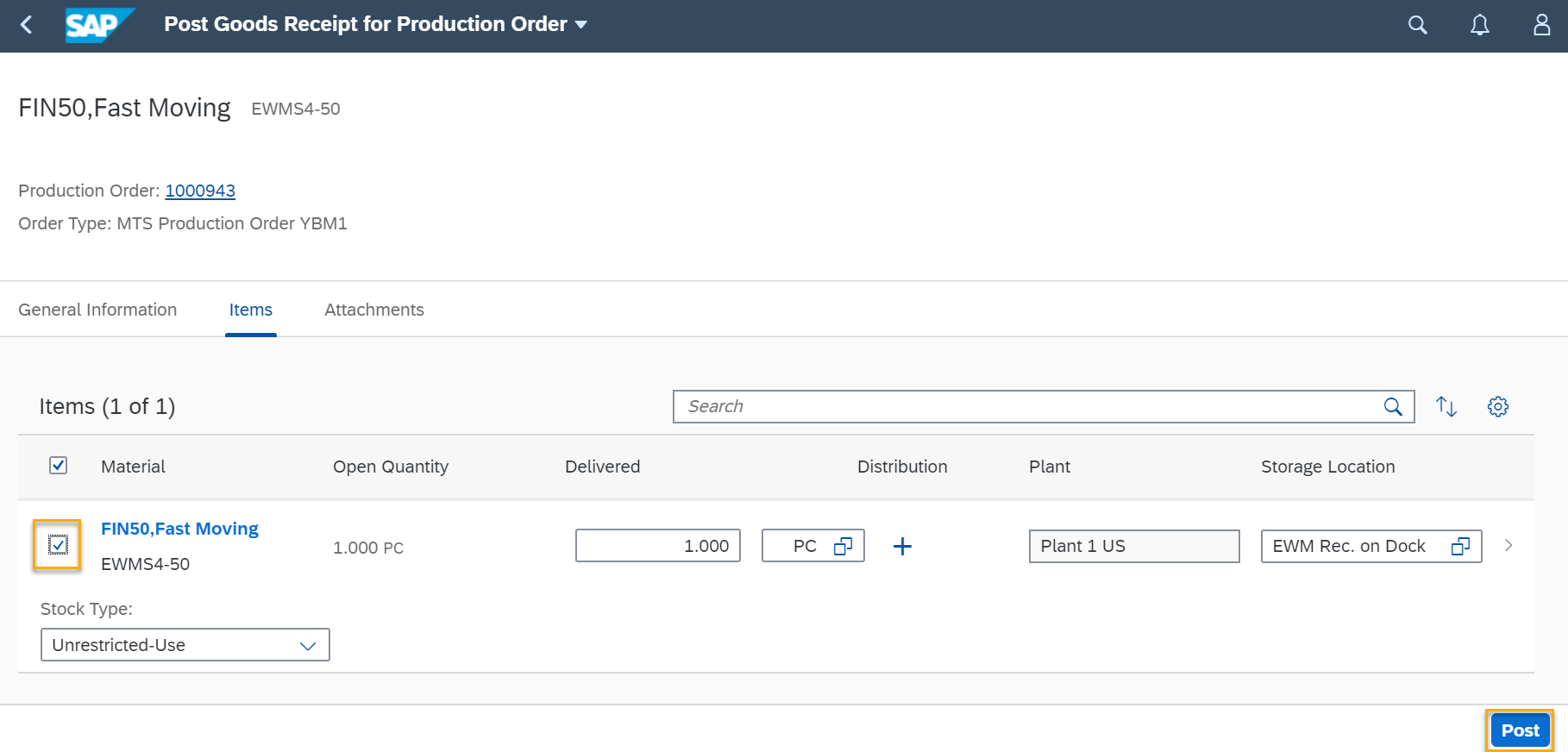

Production goods receipt

Fiori App - Post Goods Receipt for Production Order

After production order confirmation goods receipt posted. based on material storage location system post stock in to inventory management. If storage location updated in material master relavant to warehouse then system generates inbound delivery automatically.

The Inbound Delivery process will be covered in next blog post.

Production order review

Fiori App - Manage Production Orders

Production order operation confirmation updated.

Fiori App- Production Material Request

Production material request (PMR) status updated based on goods issue processing.

Conclusion

Production and warehouse consultants able to execute manufacturing production order material staging trough production material request (PMR) in S/4HANA Embedded EWM functionality.

Next Blog - WIP

I would very much appreciate your comments and suggestions.

Best Regards,

lingaiahvanam Linkedin Twitter

- SAP Managed Tags:

- SAP S/4HANA Cloud for Manufacturing,

- SAP S/4HANA Cloud for Supply Chain,

- SAP ERP,

- SAP ERP Central Component,

- SAP S/4HANA,

- EWM - Basic Functions,

- EWM - Basis,

- EWM - Delivery Processing,

- EWM - Goods Movement,

- EWM - Interfaces,

- EWM - Master Data,

- EWM - Radio Frequency,

- EWM - Shipping and Receiving,

- EWM - Warehouse Order Processing,

- LE (Logistics Execution),

- LE Warehouse Management,

- MAN Material Requirements Planning,

- MAN Production Planning (PP),

- MM (Materials Management),

- Software Logistics,

- SAP S/4HANA Public Cloud

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- SAP S4HANA Cloud Public Edition Logistics FAQ in Enterprise Resource Planning Blogs by SAP

- Integration of SAP Service and Asset Manager(SSAM) with SAP FSM to support S/4HANA Service Processes in Enterprise Resource Planning Blogs by SAP

- SAP Preferred Success: A Day in a Life in Product Change Management with Change Records in Enterprise Resource Planning Blogs by SAP

- Portfolio Management – Enhanced Financial Planning integration in Enterprise Resource Planning Blogs by SAP

- Enterprise Portfolio and Project Management in SAP S/4HANA Cloud, Private Edition 2023 FPS1 in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |