- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Serial Numbers in SAP MM

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

VKR_23

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

07-11-2023

9:44 AM

Serial Number in Material Master

Serial Numbers:

Serial number is the number which is assigned apart from the material number in SAP MM in order to differentiate between individual pieces and other material items.

- The combination of a material number and a serial number is always unique.

Serialized Inventory:

Serialized Inventory is the tracking of individual units using Unique Serial Numbers. Serial Numbers are differentiated from SKU (Stock Keeping Unit).

- SKU Numbers Identify the type of Product while Serial Numbers identify one Specific item or a part of an item.

Process Flow:

- Create the Serial Number Profile in Transaction Code in OSI2.

- Create the Material and Assign the Serial Number Profile in Material Master.

- Create the Serial Numbers in Transaction Code IQ01.

- Create the Purchase order in ME21N.

- Goods Movement in MIGO (GR w.r.t PO 101 Movement Type)

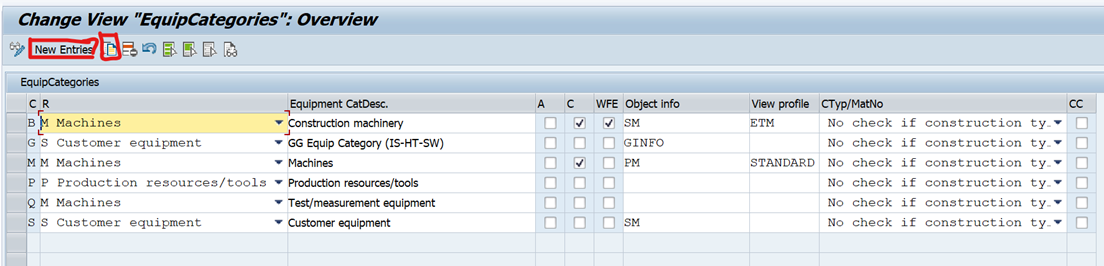

Equipment Category is used to categorize your equipment according to broad criteria, such as we have used it as Electrical Equipment, Mechanical Equipment, Instrumentation Equipment, PRT (Production Resources Tool), Vehicles also some category where material Serial Number functionality is used.

Note:

- The Numbers will be triggered based on the Equipment Category assigned to the Serial Number Profile.

- If you want to maintain your own number range, then create the Number range (either Internal/External and assigned to the Equipment category)

Configuration Path for Equipment category:

SPRO –> IMG –> Plant Maintenance and Customer Service –> Master Data in Plant Maintenance and Customer Service –> Technical Objects –>Equipment –> Equipment Categories –> Maintain Equipment Category

Transaction Code: OIET

If you want to create the new Equipment category, click on the new entries or else copy from the standard one.

- Below shown are the standard equipment in the SAP System.

Number Ranges for Equipment Category:

SPRO –> IMG –> Plant Maintenance and Customer Service –> Master Data in Plant Maintenance and Customer Service –> Technical Objects –>Equipment –> Equipment Categories –> Define Number Ranges

Transaction Code: OIEN

Click on the Change Groups tab as shown.

If you want to maintain your own Number Range to for Serial Profile Number Create a number range for and assign the number range to Equipment category.

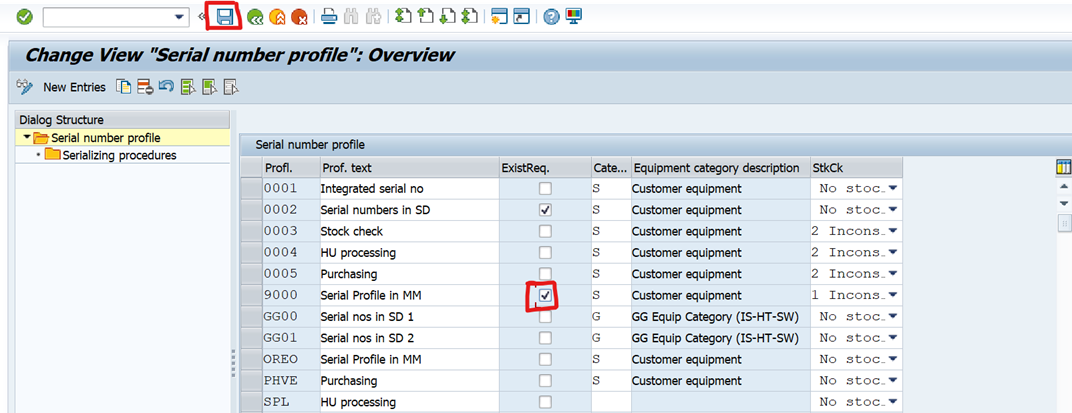

Creation of serial Number Profile:

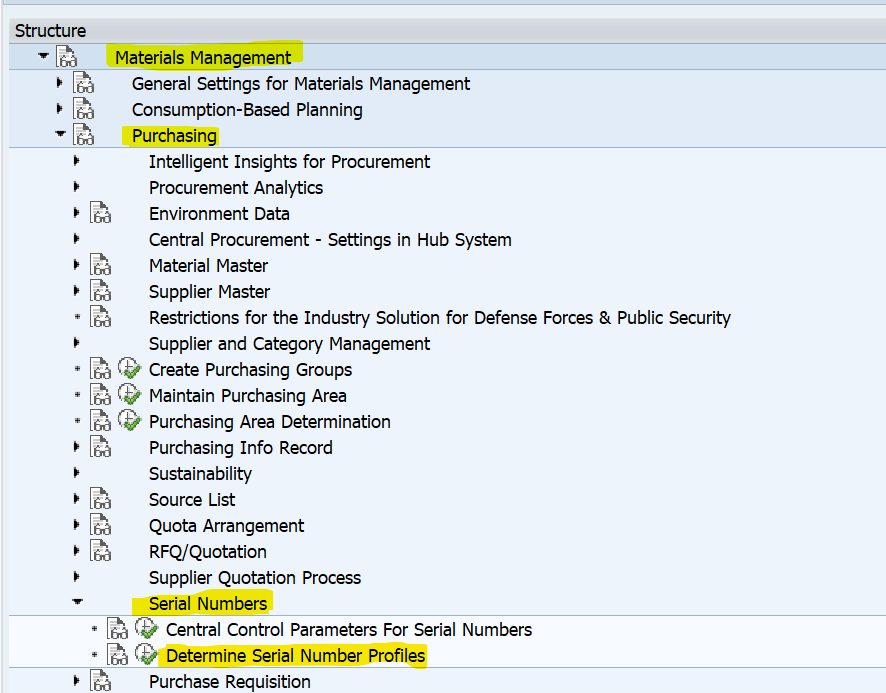

Configuration: SPRO –> IMG – Material Management –> Purchasing –> Serial Numbers –> Determine Serial Number Profiles

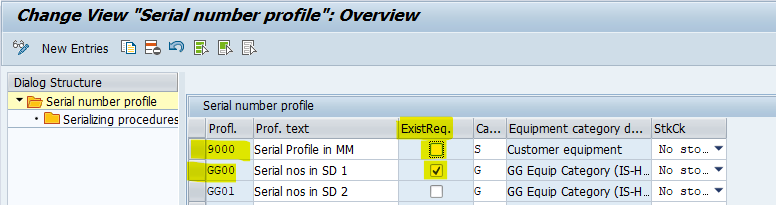

We can create the serial number profile by copying the standard one or by clicking on the new Entries.

By Maintaining the required data click on the save button.

Important fields maintain in Serial number Profile:

Serial Number Existence Requirement indicates that determines whether the serial numbers entered for a business transaction need to be created first as a Master Record in the system.

Use:

- If the indicator is set, the serial numbers must be created before creating Material Master in the system.

- If this indicator is not set, the serial numbers are created during the business Transaction.

Stock check for Serial Numbers states whether the system should perform a stock check during serial number assignment. If it should, it also establishes with what type of notification (Warning or Error) the system reacts in the event of stock inconsistencies with Inventory Management.

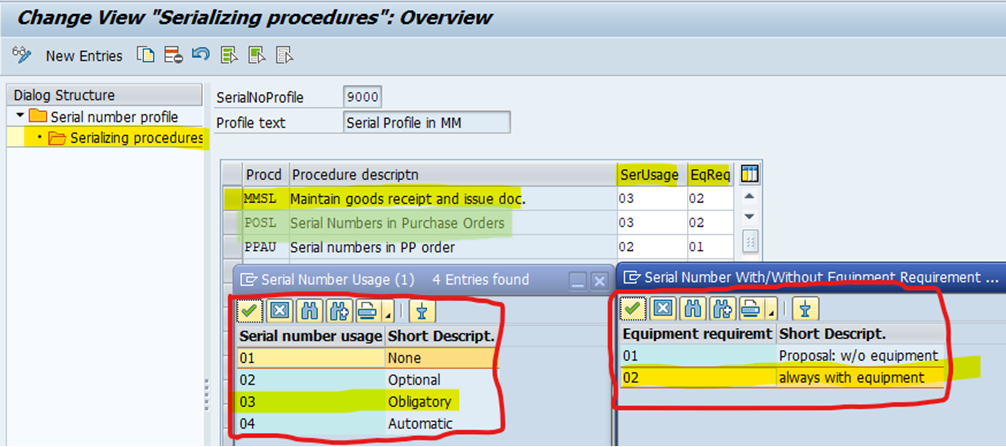

Serializing Procedures:

It is a four-digit identification code which describes a serialization Procedure. Define on the business requirement you can set different scenarios for a serial number profile.

Select the line item of the serial number profile and click on the Serializing Procedure.

MMSL and POSL Procedure is the standard one from MM side.

SerUsage (Serial Number Usage)

Indicator that determines for a business Transaction, Whether

- No Serial Numbers are assigned.

- Serial Numbers can be assigned.

- Serial Numbers must be assigned.

- Serial Numbers are assigned automatically.

Dependencies:

If the serial numbers are automatically assigned during a transaction, the dialog box for creating serial numbers is not displayed.

If we can assign the serUsage for the procedure MMSL and POSL we can get the error like

Eqreq (Equipment Requirement)

Entry that determines whether or not an equipment master record should be created for each number when assigned Serial Numbers.

Use:

- If you choose the indicator “Default: Without Equipment”, the user can later decide when assigning serial numbers in the dialog box, whether an equipment master record still be created.

- If you choose the indicator “With Equipment” this is binding for the user. The indicator cannot be reset.

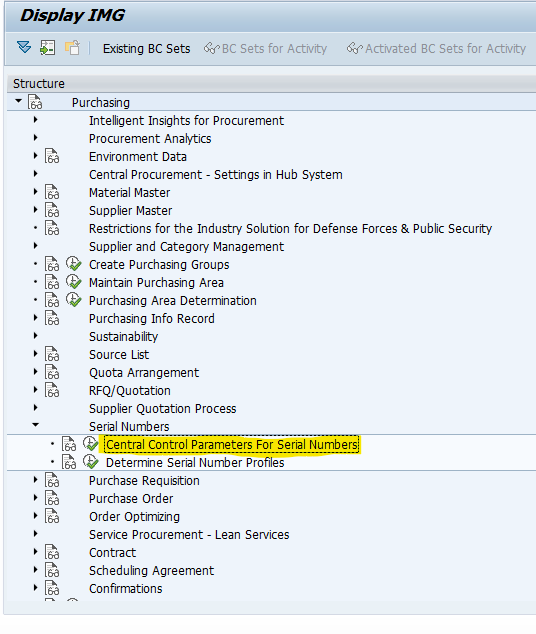

Central Control Parameters for Serial Numbers:

Configuration: SPRO –> IMG –> Material Management –> Purchasing –> Serial Numbers –> Central Control Parameters for Serial Numbers

Transaction Code: OIS1

In this step, you define a central default equipment category for serial number management. This Equipment category is proposed by the system cannot find an equipment category in the serial number profile a serialization operation.

Note: If you create master records for serial numbers for serial number manually the system automatically proposes the default equipment categories defined here. The Internal number range of the equipment category you selected is copied automatically.

Serial Number Range (Internal Number Assignment) Number that determines how documents are to be numbered by the system. It indicates which number range is relevant for a document type.

The numbers assigned via this setting are irrelevant for actual serial number management, since you work with serial numbers or material numbers in the application transactions. The numbers assigned here, however, are keys for the equipment file as a basic equipment master record is created in the background for each serial number.

For this reason, the internal number range of the selected equipment category will be proposed.

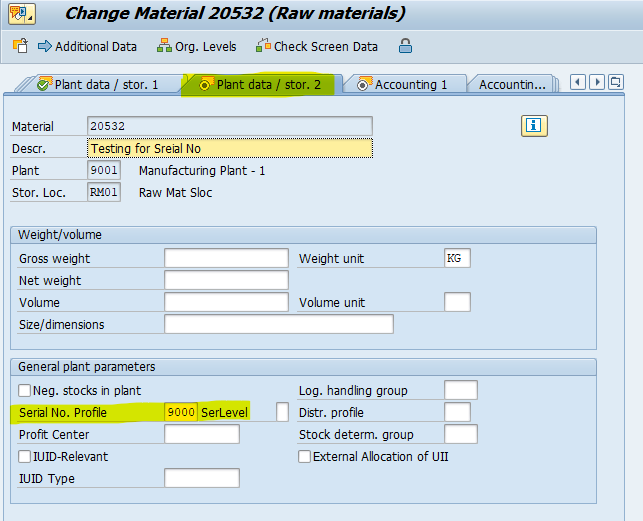

Assign the Serial Number Profile in Material Master:

We can assign the serial number Profile in

- Sales General/Plant data

- Plant data storage 2

If we can maintain the serial number profile in the Sales General/Plant data, the serial number profile is automatically updated in the Plant Data Storage 2.

By Maintaining the required data click on the save button.

Material Created under the number 20532

Create the Serial Number in Transaction code in IQ01:

The Initial Screen Appears like

By Entering the Material Number and Category click on the Existing Serial Number list tab as shown.

In this Transaction we can create serial numbers manually one by one.

Stock Type is the Mandatory field. (I.e., Unrestricted use or Quality or Blocked)

By Maintaining all the data click on the save data.

Note:

- We can create the serial numbers directly in PO without creating in the IQ01 Transaction code.

- If you want to create the number of serial numbers at a time in the Transaction code in IQ04.

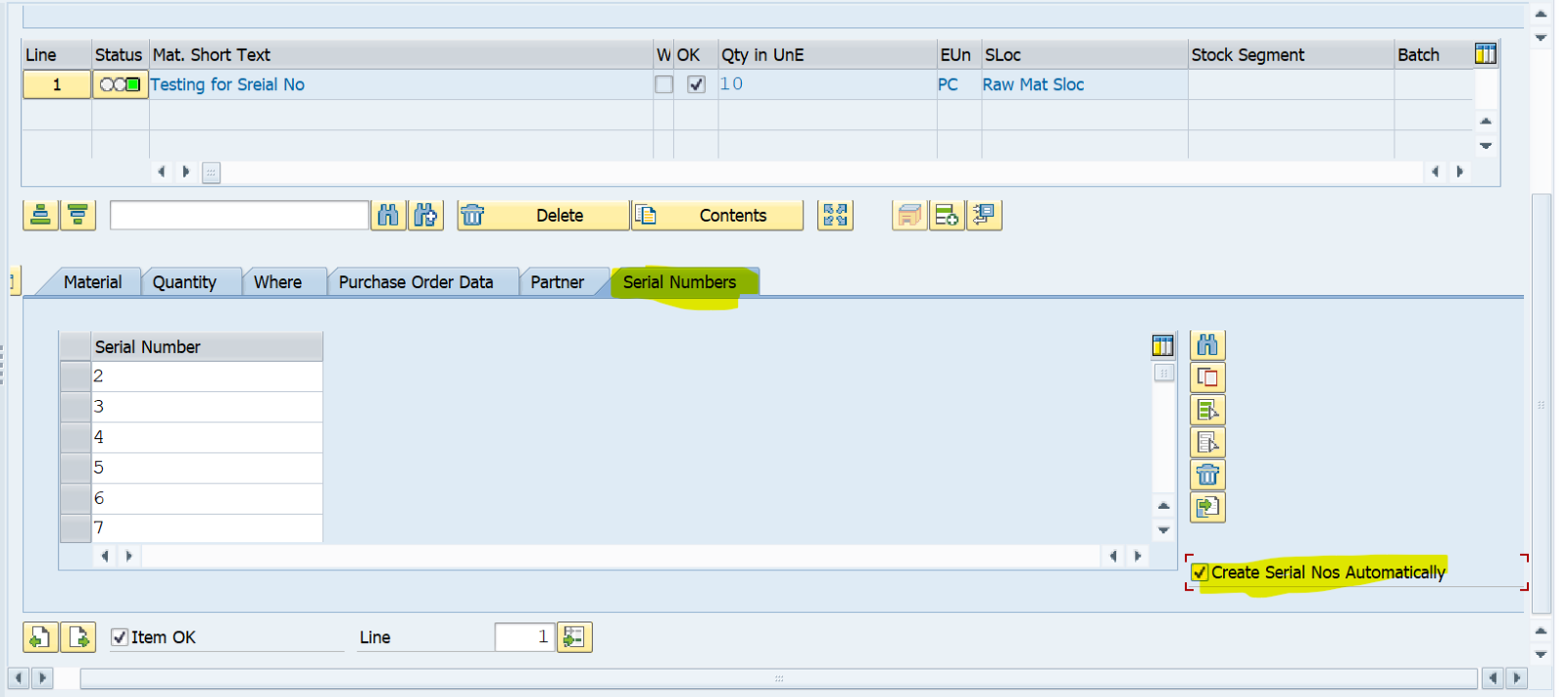

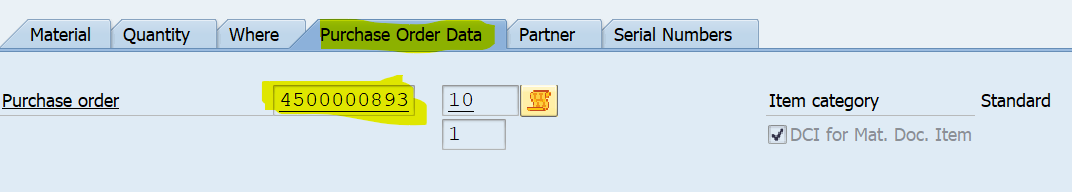

Create the Purchase order in ME21N:

Enter the required fields and click on the save button.

Here as I am creating the PO for 10 Quantity

By Entering the Quantity, the system shows the Error

By clicking on the Enter button the system shows the Pop-up screen.

- We can Enter manually Serial numbers for the ordered Qty.

- By clicking on the Create serial number Automatically the system creates the serial numbers automatically.

Standard PO created under the number 4500000891.

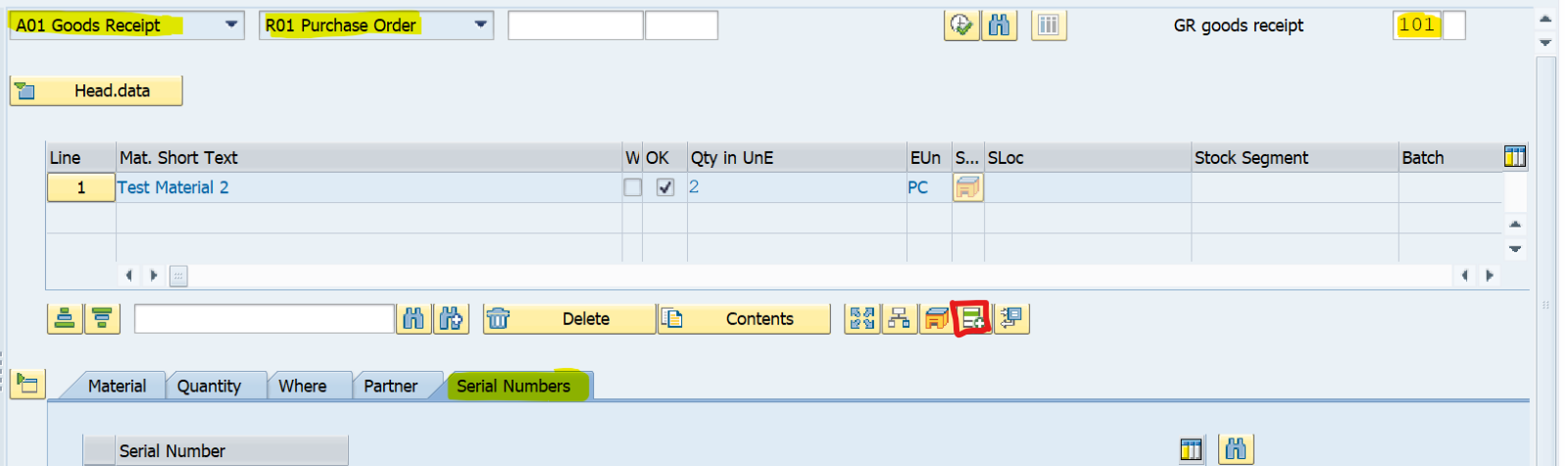

Goods Movement: (MIGO)

Goods Receipt – Purchase order (Movement type 101)

By Maintaining the data click on the save button.

The serial number tab is appeared in the GR.

Material document 151 posted.

Note: Once If GR is done for the Material, then the system won’t allow the same serial number again for the same Material.

If you maintain the tick mark the system will allow you to enter the serial numbers manually instead of creating automatically.

We want to create the Serial numbers manually in IQ01 for the number of Quantities maintained in the Purchase order then only the system accepts the serial numbers in the PO or else the system throws an error.

Standard PO created under the number 4500000931.

Goto the Transaction code IQ03 or IQ09 to see the serial numbers for the material.

The remaining Process is same we can do Goods Movement and Invoice Verification.

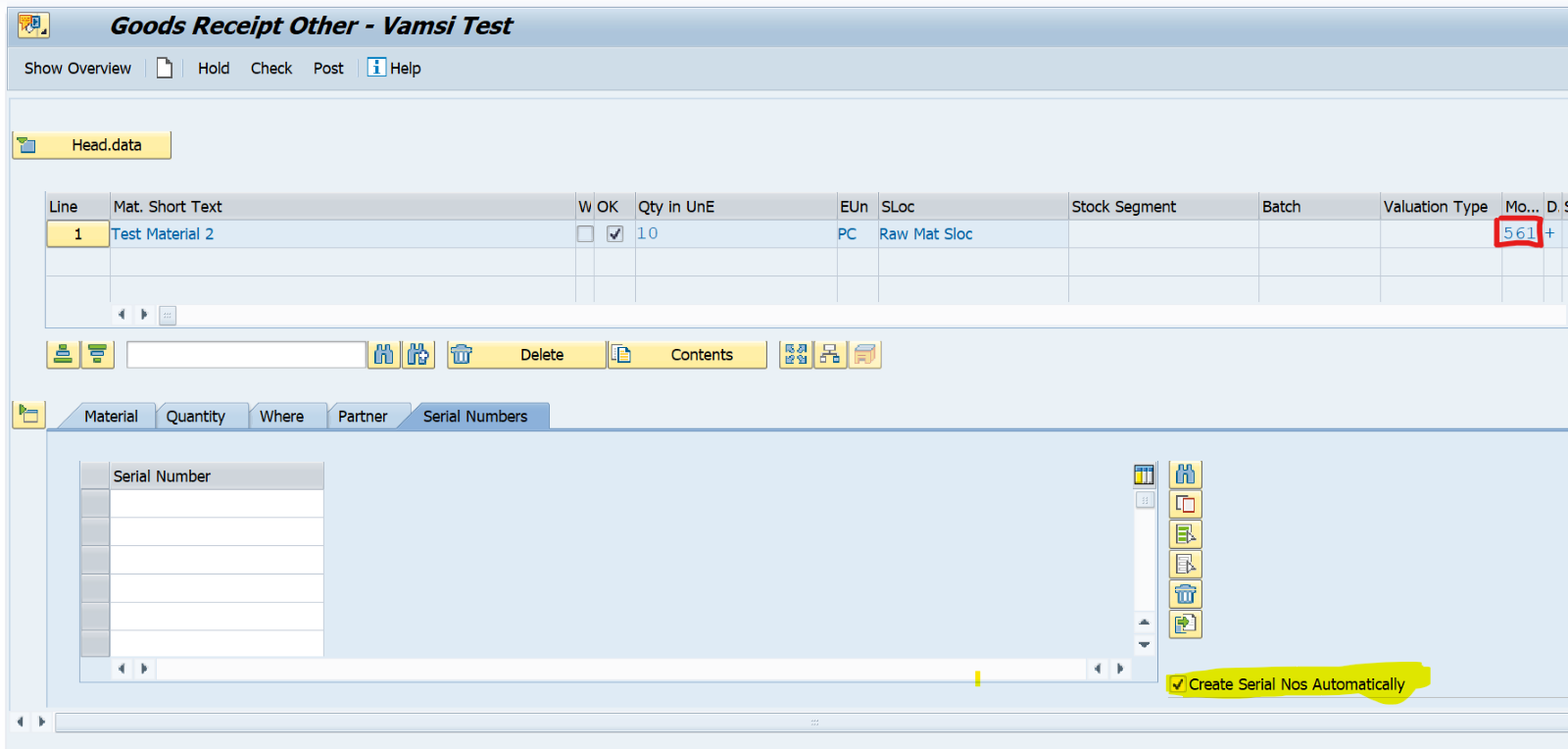

Creation of Serial Numbers in Goods Receipt directly without PO

We can also create Serial Numbers in Goods Movement directly without creating the Purchase order.

Hera I am creating the new material in MM01.

Maintain the Serial Number Profile in Plant data/Storage2 tab.

Material 6000181 created.

Next, we can do directly Goods Movement in MIGO.

- Goods Receipt –> Others (Movement Type 561)

- Goods Receipt –> Others (Movement Type 501)

- Goods Receipt –> Others (Movement Type 101)

- Goods Receipt – Purchase order (Movement Type 101)

- For the GR w.r.t others and w.r.t PO we have to maintain Purchase info Record to pick the net price for the material.

- In both scenarios GR w.r.t PO and GR w.r.t to others the Purchase order number is created automatically.

1st Scenario:

Goods Receipt –> Others (Movement Type 561)

Enter the Material, Quantity, Plant and Storage Location.

Click on the Serial Numbers and select the create serial Numbers Automatically.

Click on the check button to see any incompleteness in the data if all the document data is ok click on the post or save button to post the Material Document.

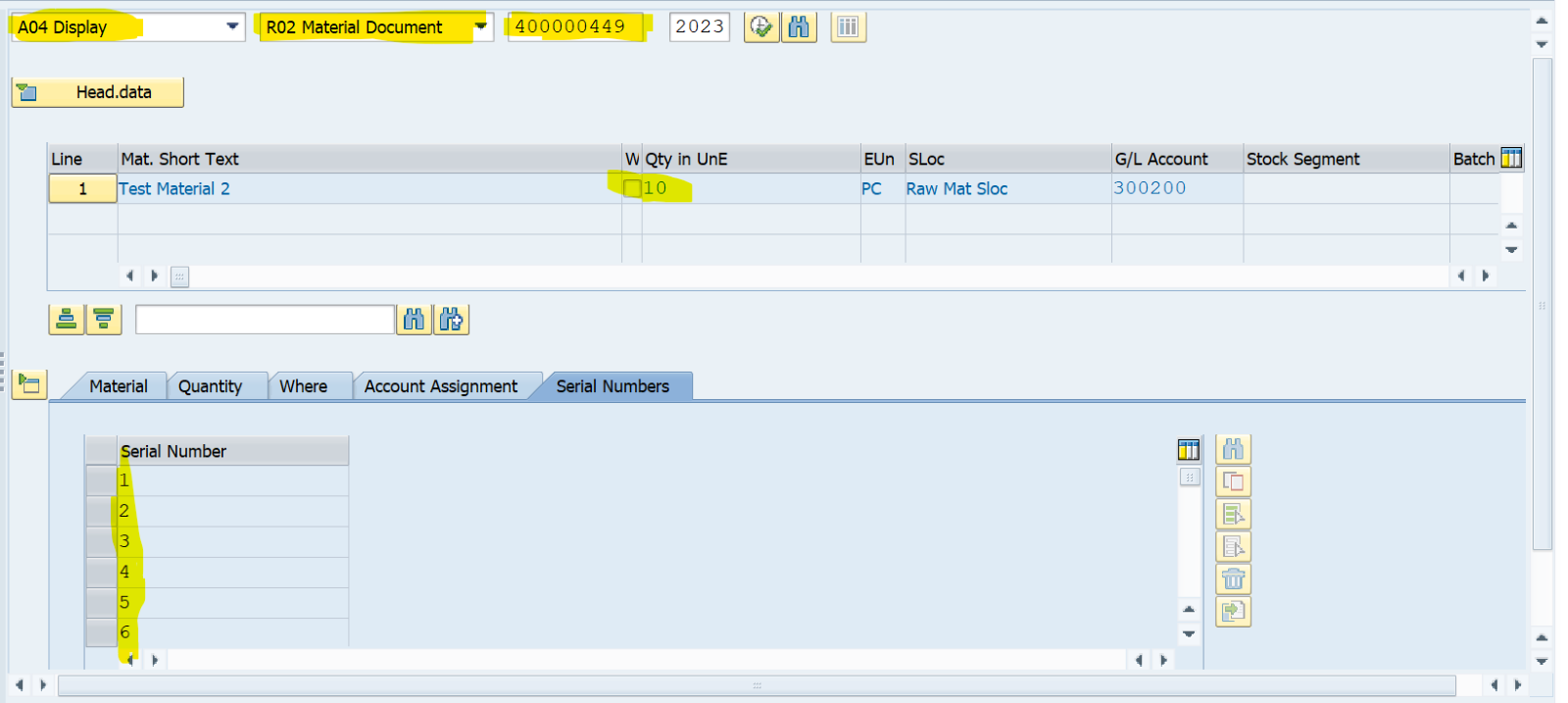

Material document 400000449 posted.

Now display the Material document

If we have any Queries, we can check in the IQ01 Transaction code.

2nd Scenario:

Goods Receipt –> Others (Movement Type 501)

Enter the Material, Quantity, Plant and Storage Location.

Click on the Serial Numbers and select the create serial Numbers Automatically.

Click on the check button to see any incompleteness in the data if all the document data is ok click on the post or save button to post the Material Document.

- Here I am creating the serial numbers for the same material, so serial numbers count starts from 11 onwards.

Material document 400000451 posted.

Now display the Material Document.

If we have any Queries, we can check in the IQ01 Transaction code.

3rd Scenario:

Goods Receipts –> Others (Movement Type 101)

Material document 400000452 posted.

Display the Material Document.

4th Scenario:

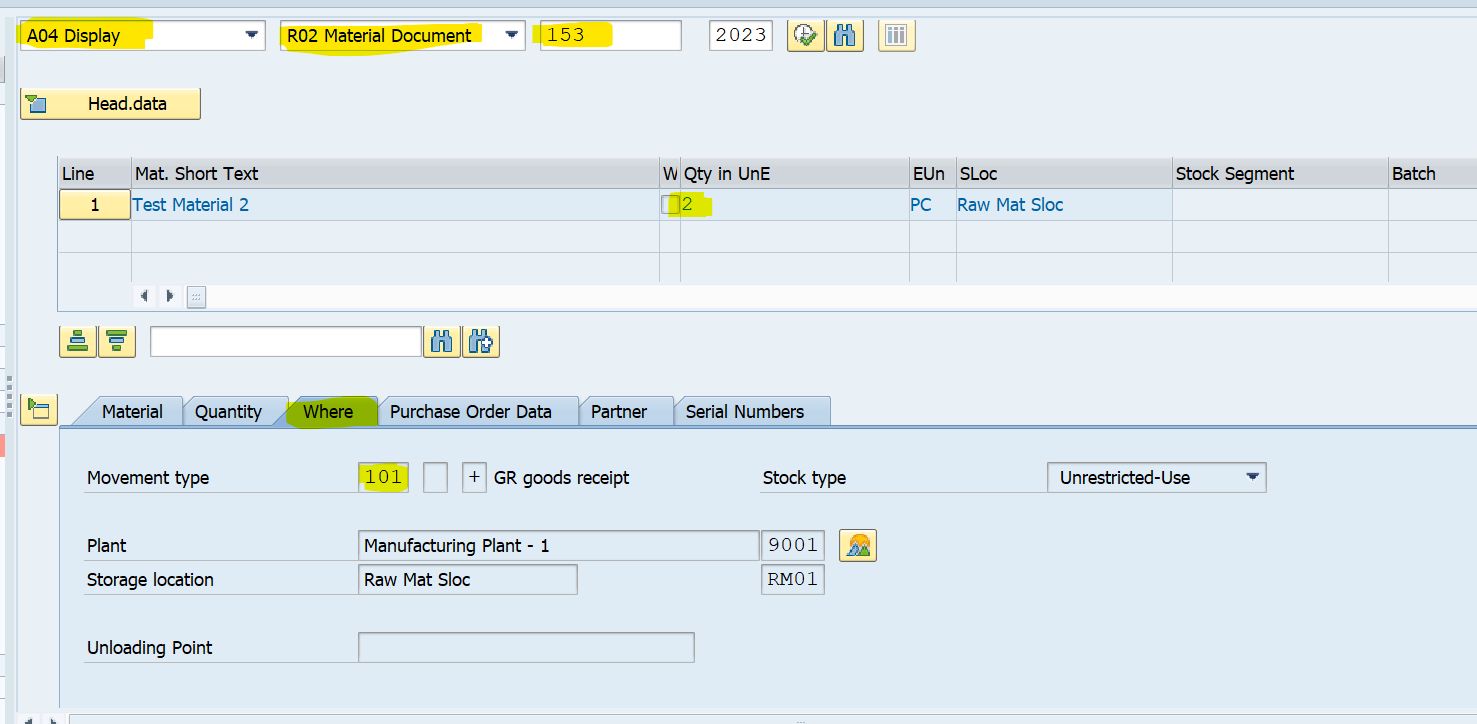

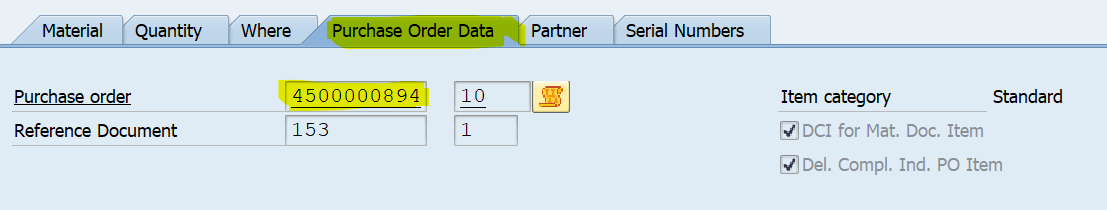

Goods Receipts –> Purchase order (Movement Type 101)

Material document 153 posted.

Display the Material Document

Conclusion:

To conclude, we can say that serial numbers are an important part of the SAP system, as they allow for unique and accurate tracking of products.

They can be used to track the movement of products within the company, as well as to record important information such as production dates and location.

I think this blog is useful.......!!

- SAP Managed Tags:

- SAP S/4HANA,

- MM Inventory Management,

- MM Purchasing

6 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- CDS View to Get Billing Document Number and Sales Order Number in Enterprise Resource Planning Q&A

- CEWB: error in component allocation without change number in Enterprise Resource Planning Q&A

- CEWB for component allocation: change number is required in Enterprise Resource Planning Q&A

- Production order number range in Enterprise Resource Planning Q&A

- List of cancelled shipment numbers against Order number or PO number or Material number required in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |